Algonomy Is Positioned as a Strong Performer in Forrester’s Retail Planning Wave

Our Customers

Leading retailers and brands across the globe have optimized their supply chain and merchandise planning and execution with Algonomy.

Accurate Replenishment Planning for Improved Inventory Management

10%

10%Inventory Cost

75%

75%Out-of-Stock Instances

10-30%

10-30%Wastage

99%

99%Shelf Availability

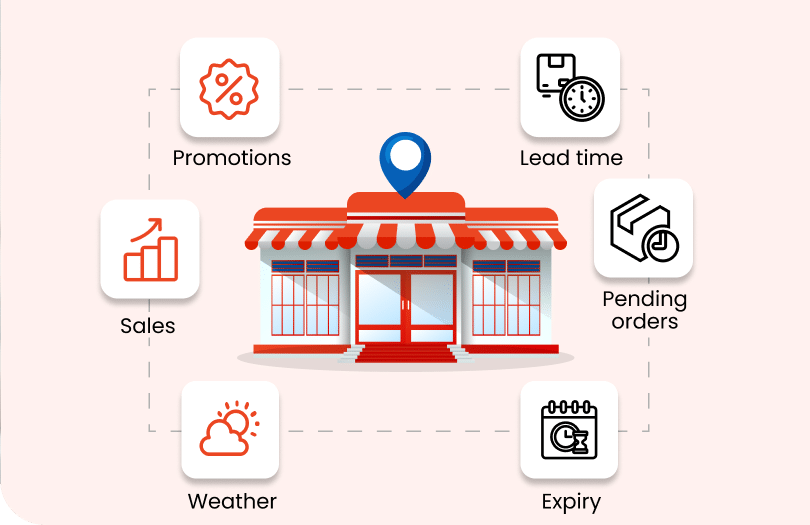

Effortlessly Adapt Replenishment Plans To Hyperlocal Demand Patterns And Supply Chain Dynamics

Maximize Accuracy by Going Hyperlocal

Leverage Algonomy’s unique ML-based algorithms that dynamically adjust to SKU-store level demand patterns and supply chain disruptions, delivering hyperlocal precision to replenishment plans.

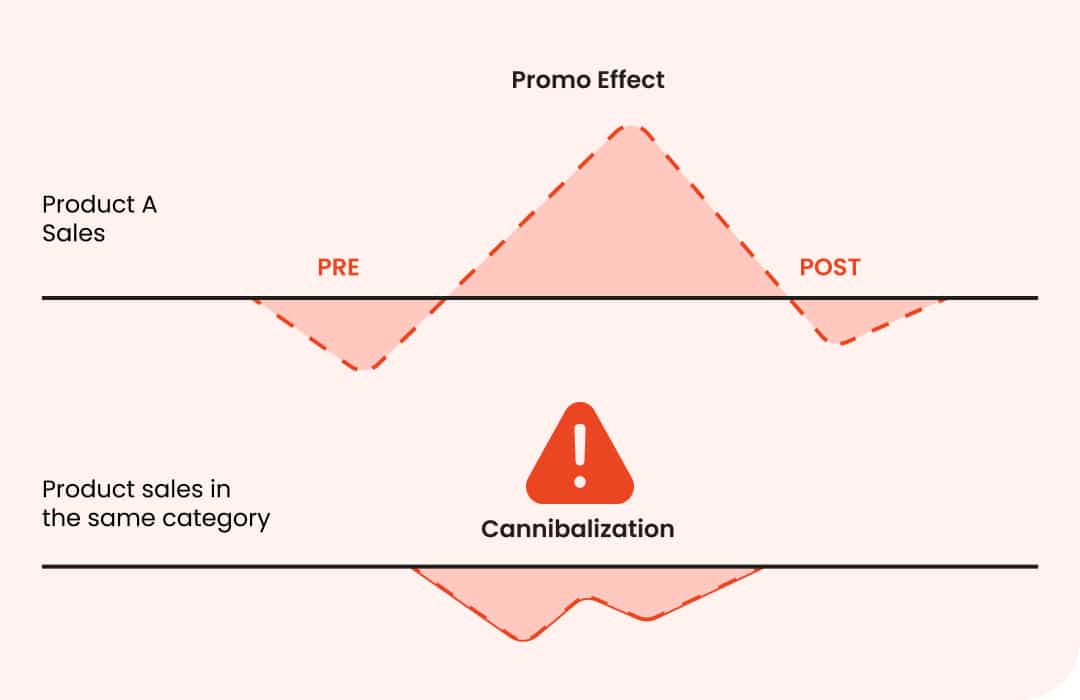

Curb Cannibalization Chaos

Effectively handle in-store product cannibalization by dynamically balancing demand between products, considering promotions and availability. Automatically adjust replenishment levels up or down to align with the shifting market.

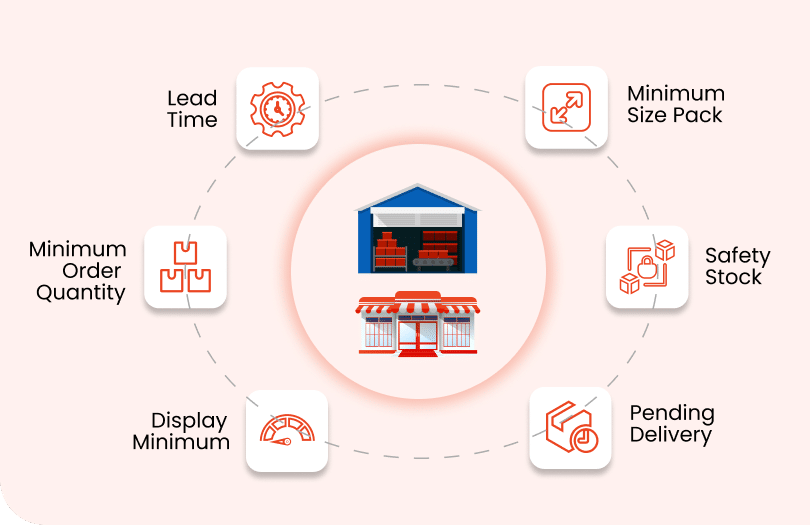

Mitigate Supply Chain Disruptions

Safeguard your stores and warehouses from supply chain disruptions using adaptive self-learning models that optimize replenishment plans by modeling variations in lead times, fill rates, safety stock, and pending orders.

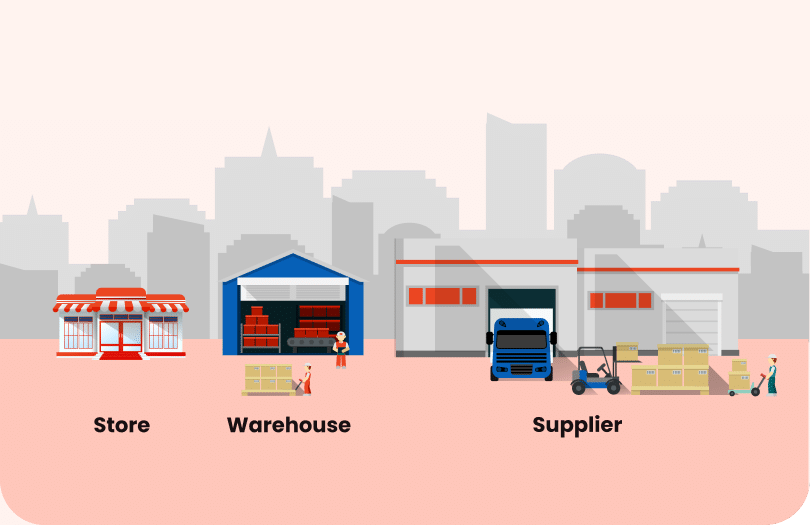

Optimize Multi-echelon Inventory

Automatically optimize inventory across the supply chain by supporting Direct Store Orders, Stock Transfer Orders as well as Warehouse Orders with one of the best replenishment planning solutions.

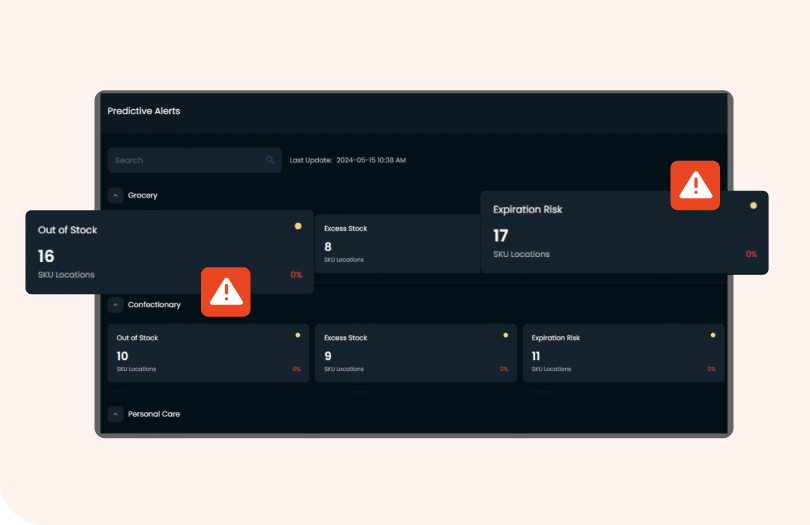

Pre-empt Risks with Predictive Alerts

Mitigate future inventory headaches and maximize efficiency with predictive alerts for days of stock situations, excess stock, and expiring products, for replenishment optimization and taking corrective action proactively. These insights enable timely replenishment optimization and ensure the right products are available while minimizing overstock and shortages.

End Manual Hassles

Handle data roadblocks such as sparse, noisy data, outliers, and new product introductions effortlessly with custom retail-tuned algorithms for replenishment planning, freeing your team to focus on business.

Discover Order Right’s Innovative Forecasting Framework for Unparalleled Accuracy. Learn More

Maximize Replenishment Accuracy to Elevate Supply Chain Outcomes

Higher Availability

Ensure your stores and warehouses never run out of stock with Order Right. Its unique hyperlocal forecasting and replenishment technique comprehends demand and supply fluctuations at the minutest product and location levels, enabling you to accurately predict future inventory needs and replenish accordingly.

Improved Inventory ROI

Achieve greater accuracy in replenishment planning with Order Right, giving you the freedom to operate with less inventory without risking stockouts. By reducing your inventory days, Order Right helps free up your cash flow and better manage your inventory.

Reduced Shrinkage And Wastage

Order Right’s ML based algorithms optimizes your order plans by considering not only demand factors but also supply-side factors like lead time and MOQ, as well as product-specific factors such as expiry date and shelf life. This comprehensive approach reduces shrinkage and wastage across the supply chain.

Enhanced Planning Efficiency and Transparency

Automate routine forecasting, replenishment planning, performance analysis, and more, with actionable insights delivered via a single unified interface to reduce man-hours and increase focus on strategic business decision-making.

Explore Client Success Stories Powered by Algonomy's Intelligent Replenishment Planning Solution

Helpful Resources

Explore our resources, case studies, infographics, eBooks, and more for a deeper understanding.

A Leading European Pharmaceuticals Retailer Cracks Key Supplier Collaboration Challenges

A Major US-based Convenience Store Retailer Takes Its Supplier Collaboration to the Next Level

How Keells fostered true supplier collaboration and achieved remarkable efficiencies in supplier processes

Leveraging Automation and Custom-Built Data-Sharing Framework to Streamline Supplier Collaboration

A Leading Grocery Retailer in South East Asia Slashes Stockouts by 63% and Inventory Costs by $ 1.5 Million

A Leading Pan-Asian Health, Beauty, and Wellness Retailer Shrinks OOS by 60% and Unlocks a 62% Increase in Inventory Turnover

Take your replenishment planning to the next level with Order Right.

-

10%

10%Inventory Costs

-

75%

75%Out-of-Stock Instances

-

10%

10%Wastage

-

99%

99%Shelf Availability

Get in Touch with Our Experts