As businesses embrace technology-driven capabilities globally, the word collaboration assumes a critical stance, especially in industries that thrive on seamless functioning across multiple disparate components. Retail is an epitome in this regard, with its success hinging on transparency, responsiveness, integrated management, and comprehensive visibility, among other factors.

This is exactly why supplier collaboration matters for every retailer aiming to achieve greater profitability, better control, and precise strategy stemming from streamlined operational management and data-driven insights.

While supplier collaboration is the essence of healthy and profitable retail supply chains, the space is riddled with multiple challenges, that spur inefficiencies, ultimately chipping away at the bottom lines.

In this blog, we discuss:

- What does supplier collaboration mean for a retailer?

- Why is supplier collaboration important?

- What are some critical challenges faced by retailers while collaborating with suppliers?

- How do we leverage automation for supplier management?

- What are the various benefits of automation-driven supplier collaboration?

- Some industry trends, success stories, and data-rich insights related to supplier collaboration in retail.

What Is Supplier Collaboration?

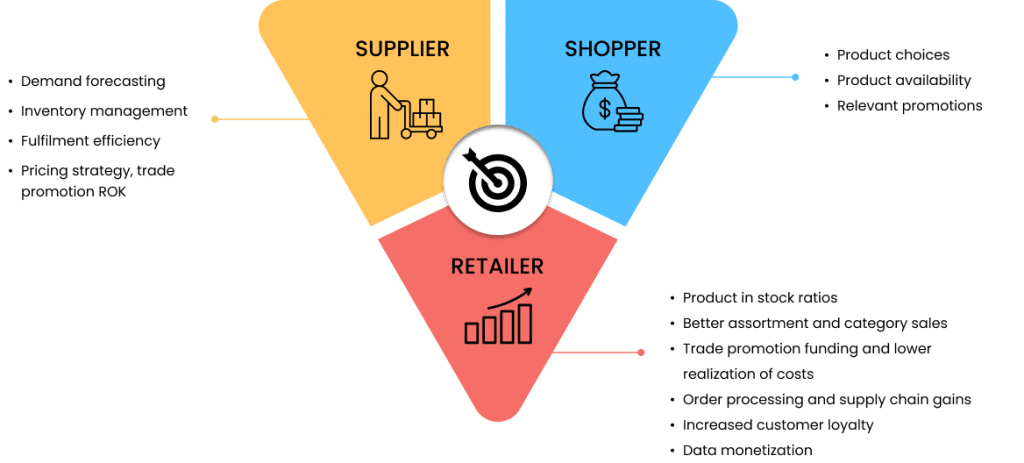

Supplier collaboration means retailers and suppliers working together in a streamlined and integrated manner to drive strategic decisions and get complete visibility over movements, processes, and operations, for truly seamless functioning.

Collaboration in supply chains is essential for reliable, transparent, and efficient operations as it enables both retailers and suppliers to have a unified view of all separately working entities in the supply chain ecosystem.

From invoices to shipment movements, product data to shipment data, supply-side deviations, and inventory to supplier performance – an intelligent supplier collaboration platform enables retailers and suppliers simultaneously.

Improved collaboration in the supplier network directly influences as much as 20% of total revenue apart from other key metrics such as customer experience and cost of operations.

How Is Supplier Collaboration Different From Supply Chain Collaboration?

While the overall essence remains the same, the terms supplier collaboration and supply chain collaboration vary in their meanings and processes from one industry to another.

Supply chain collaboration will encompass the 360-degree collaboration spanning suppliers, retailers, manufacturers, logistics providers, warehousing providers, technology providers, etc.

On the other hand, supplier collaboration focuses on the entire ecosystem of retail-supplier interactions and operations, such as product cataloging, electronic data interchange capabilities, inventory data, supply-related events, like lead times, supplier performance KPIs, payments, etc.

So, supplier collaboration platforms enable both retailers and suppliers to operate in an integrated manner through a unified interface in a truly seamless manner. Retailers are always on top of all supply-side events, can easily manage new product introductions, take care of rapid supplier onboarding and deboarding, and ensure a firm grip over all the supplier-related information.

Supplier relationship management, data analytics & reporting, contract management, and category management – are the four “directly related to supply chain” critical initiatives with low maturity (top business priorities on the procurement initiatives side.

Be it promotions, supplier rebates, billings, claims, settlements, or any other critical process, intelligent supplier collaboration solutions can transform how retailers and suppliers work. They easily overcome the tedious manual individual interactions with centralized communication interfaces and help retailers bypass cultural, communication, and regional barriers like language, etc., to operate effortlessly.

Why Is Supplier Collaboration Important?

As per a recent 2024 survey report by The Hackett Group, operational agility improvement is a critical business objective for 17% of organizations and a high priority for 43% of them.

Retailer-supplier collaboration is the foundation of supply chain resilience, robustness, visibility, and transparency. All of these are the most important factors for supply chain success.

#1 – Improved Supply Chain and Inventory Planning

A lack of mutual trust and communication tops the list of challenges for 63% of retailers and 52% of suppliers.

With the right collaboration platforms, retailers and suppliers can easily overcome communication barriers and unlock greater transparency in terms of consignment, shipment lifecycle, inventory, supply side deviations, and finance operations. They can stay on top of any disruptions and fraudulent activities and work in a mutually trustworthy manner.

#2 – Reduced Operational Costs

Studies reveal that up to 25% of supply chain data is inaccurate due to siloed information. Further, poor data quality costs organizations an average of $12.9 million every year.

Further, inefficient or incorrect invoicing and claims settlements incur huge costs to businesses across different segments of the retail industry. With a proper supplier management interface, retailers can find all the required information in one place whenever required. They can instantly cross-check the claims, approve settlements, and calculate rebates automatically, reducing costs.

Another important aspect of reducing supplier-related costs in retail supply chains is sustainability. Manually managed inventory is a sob story of overstocks, obsolescence, stockouts, and wastage, translating into lost sales, capital lock-ins, and high inventory holding costs.

ML-driven supplier management software inherently overcomes these challenges with built-in workflow automation that can be customized as per business requirements.

#3 – Supply Chain Efficiency

Right from man hours to the number of steps involved in completing a task, and real-time data insights – supplier collaboration platforms offer 360-degree streamlining of retailer-supplier operations.

Demand planners no longer have to grab hold of procurement staff or supply chain professionals to get real-time insights on inventory availability. Likewise, suppliers no longer have to wait for multi-party approval via multiple channels for operations.

As all the information for all the channels and functions is disseminated efficiently via a single unified interface, that is secure and transparent, retailers as well as suppliers can unlock more supply chain efficiency and greater savings.

#4 – Product Lifecycle Management

Managing new product introductions, products with shorter lifecycles, and challenging categories, such as imported eatables, or products with short shelf life such as ultra-fresh categories are some of the most critical and challenging entities to manage.

Manual and traditional systems don’t offer any special capabilities to retailers or suppliers to manage the nuances and rely heavily on human involvement. This affects operational efficiency and increases category management costs.

Improving supplier collaboration with automated supplier management software enables retailers to reduce the effort involved in managing the entire product lifecycle via digitized cataloging, supplier onboarding, electronic data interchange, and other such capabilities.

They can simplify new product introductions and challenging categories digitally, improving efficiency, profitability, and inventory ROI by strategic sourcing and inventory positioning.

Critical Challenges Faced by Retailers While Collaborating With Suppliers

#1 – Communication Challenges

Manually managed supply chains or supply chains with traditional management infrastructure lack transparency, and suffer from disparate functions. Most of the retailer-supplier collaboration relies on individual connections and is inefficient.

#2 – Multiple Interfaces

Working with multiple suppliers means toggling among multiple management interfaces, some of which might not be integrated with the existing tech infrastructure. This spurs inefficiencies, and redundancies, as retailers are unable to have a comprehensive understanding of supply-side processes.

#3 – Siloed Operations

Managing every supplier in a disparate manner also affects retailers’ understanding of key performance metrics. They cannot measure the efficiency and productivity of each supplier, let alone the overall supply chain efficiency.

Further, the inability to have a wholesome inventory picture at a particular time affects the planning, skewing the demand and inventory processes as well.

#4 – Lack of Visibility and Transparency

Visibility and transparency degrade across the multiple tiers in a supply chain, which is detrimental to the overall efficiency and effectiveness of the retailer-supplier ecosystem, where multiple stakeholders are interconnected at multiple levels for multiple products and services.

While 45% of global supply chains are expected to be autonomous by 2035, 45% of businesses report limited supply chain visibility, and only 15% of CPOs report visibility beyond Tier 1 suppliers.

#5 – Mutual Trust and Reliability

Manually managed supplier ecosystem often spurs mistrust among the stakeholders, thereby degrading the overall reliability. As collaboration mainly relies on individual communication channels, the response times stretch and delays in responding to inquiries can lead to a 20-30% increase in lead times, impacting overall supply chain efficiency.

Leveraging Automation for Supplier Collaboration in Retail

Automation transforms the entire supplier collaboration process by digitizing processes and optimizing workflows in an intelligent manner. Retailers can easily streamline supplier management via built-in workflows that can be customized to their business needs and nuances.

Automation supplier collaboration platforms empower retailers by unifying the entire supply-side ecosystem and integrated management capabilities delivered via an intuitive dashboard interface. Retailers can easily onboard new suppliers within minutes, automate finance operations, create digital product catalogs, and optimize management across the entire value chain.

They can track the shipments in real time, manage supply-side deviations with predictive alerts, and get actionable insights for strategic business decisions.

Another powerful benefit of automated supplier management is the ability to track and measure individual supplier performance in a centralized manner. Right from POs to invoices, and claims to order plans, retailers and suppliers can always stay on top of the right and relevant information in an accurate and timely manner.

Supplier Collaboration Automation – Benefits

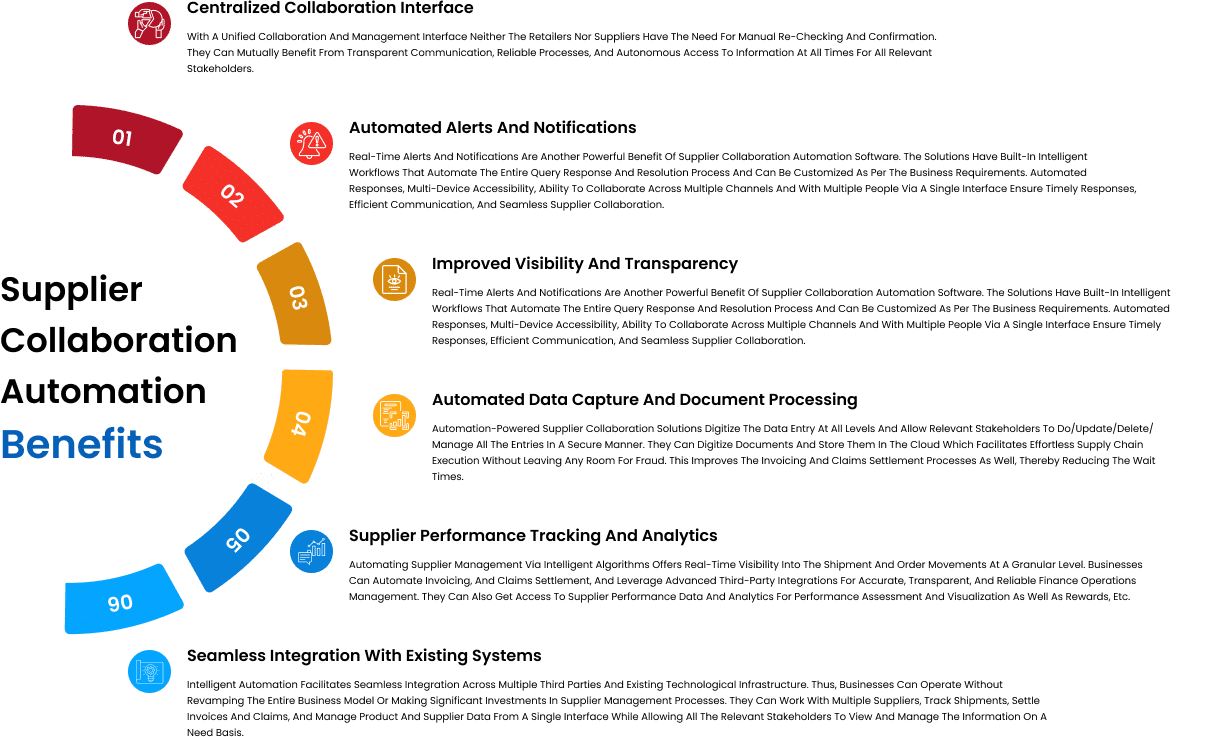

#1 – Centralized Collaboration Interface

With a unified collaboration and management interface neither the retailers nor suppliers have the need for manual re-checking and confirmation. They can mutually benefit from transparent communication, reliable processes, and autonomous access to information at all times for all relevant stakeholders.

#2 – Automated Alerts and Notifications

Real-time alerts and notifications are another powerful benefit of supplier collaboration automation software. The solutions have built-in intelligent workflows that automate the entire query response and resolution process and can be customized as per the business requirements.

Automated responses, multi-device accessibility, ability to collaborate across multiple channels and with multiple people via a single interface ensure timely responses, efficient communication, and seamless supplier collaboration.

#3 – Improved Visibility and Transparency

A unified supplier management platform integrates supplier data from multiple sources and offers a wholesome view of all processes, product information, invoices, and much more, thereby unlocking greater efficiency and strategic decision-making.

Businesses can generate highly detailed reports to make decisions at store-level, product-level, region-level, etc., and manage everything from a real-time dashboard.

#4 – Automated Data Capture and Document Processing

Automation-powered supplier collaboration solutions digitize the data entry at all levels and allow relevant stakeholders to do/update/delete/manage all the entries in a secure manner.

They can digitize documents and store them in the cloud which facilitates effortless supply chain execution without leaving any room for fraud. This improves the invoicing and claims settlement processes as well, thereby reducing the wait times.

#5 – Supplier Performance Tracking and Analytics

Automating supplier management via intelligent algorithms offers real-time visibility into the shipment and order movements at a granular level.

Businesses can automate invoicing, and claims settlement, and leverage advanced third-party integrations for accurate, transparent, and reliable finance operations management. They can also get access to supplier performance data and analytics for performance assessment and visualization as well as rewards, etc.

#6 – Seamless Integration With Existing Systems

Intelligent automation facilitates seamless integration across multiple third parties and existing technological infrastructure. Thus, businesses can operate without revamping the entire business model or making significant investments in supplier management processes.

They can work with multiple suppliers, track shipments, settle invoices and claims, and manage product and supplier data from a single interface while allowing all the relevant stakeholders to view and manage the information on a need basis.

How Can Algonomy Help?

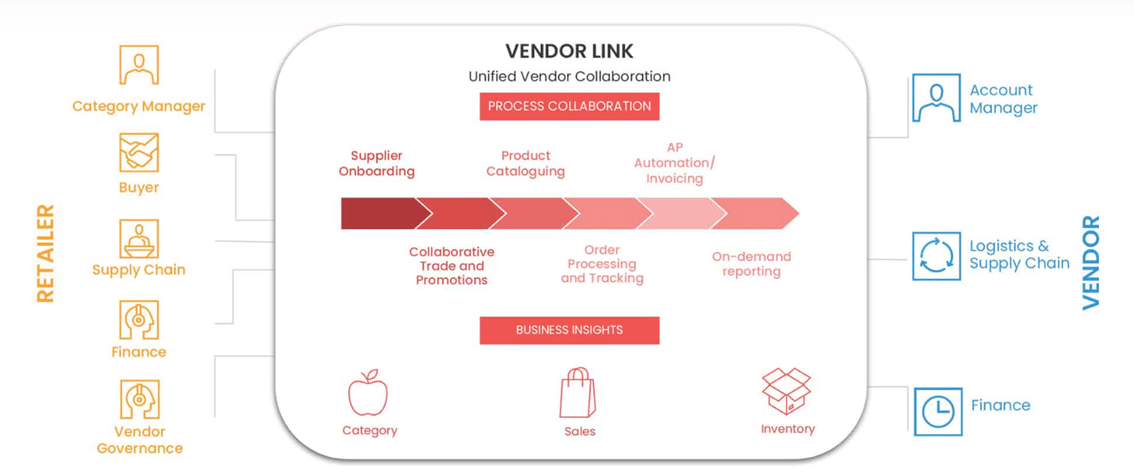

Vendor Link is Algonomy’s intelligent supplier collaboration platform that comes with in-built intelligence of ensemble AI and ML algorithms and fosters true collaboration across the entire supply chain with its exhaustive capabilities.

It helps retailers overcome the complexities of the supplier ecosystem and manage the operations as they evolve.

Here is a functionality snapshot of the Vendor Link:

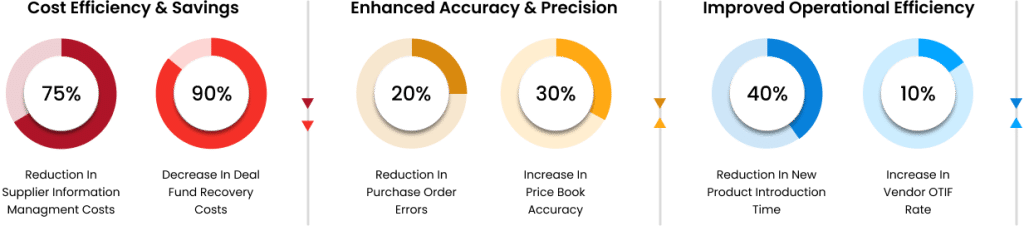

Retailers can utilize the built-in e-approval workflows and self-help portal for 70% faster vendor onboarding and reduce supplier information management costs. As supplier onboarding, product catalogs, and supply data are digitized, they can ensure 100% data accuracy, reducing errors and redundancies.

Other advanced capabilities include collaborative promotions and rebate planning, management and tracking of supplier funding, performance insights, EDI capabilities, and more, that help retailers unlock:

For more information, or to explore how Vendor Link can transform your supplier management, please get in touch with our experts today, and schedule a personalized free demo.

in Sweden from 7 - 8 October 2025. Pre-book a meeting to connect with our

product experts.

in Sweden from 7 - 8 October 2025. Pre-book a meeting to connect with our

product experts.