The global food & grocery retail industry is a $12 trillion market, but continues to bleed value – $1.77 trillion (in 2023) due to inventory distortions. Despite demonstrating an impressive rate of technology adoption, stockouts and overstocks continue to be a thorn in the side. Stats reveal that in 2023, retailers incurred losses amounting to $1.2 trillion from stockouts alone.

Apart from affecting the potential revenue from sales, stockouts also degrade customer experience, affecting customer loyalty directly. Likewise, overstocks not only contribute to capital lock-in, but they also lead to wastage, markdowns, and expiry, and affect sustainability.

What makes optimizing replenishment such a challenge in food and grocery retail, and why do inventory distortions keep being a thorn in the paw for retailers worldwide?

Here, we explore the answers and outline the solutions that actually work!

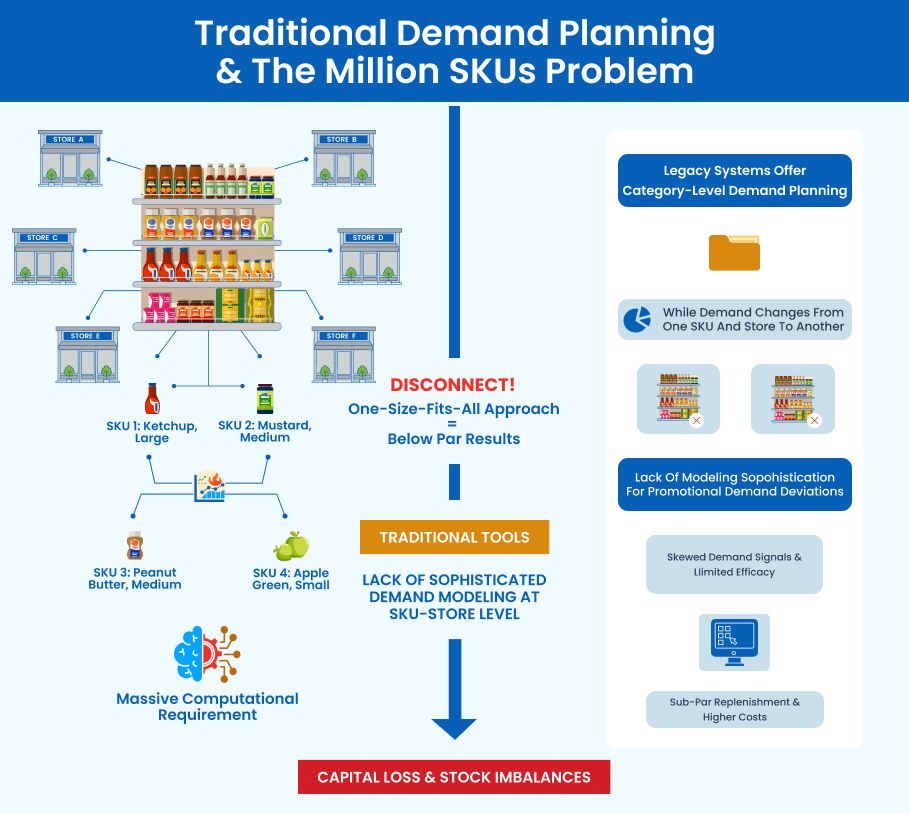

Optimization at Scale: The Million-SKU Problem

Food and grocery retail operations span millions of SKUs across hundreds of locations. Now, in an ideal scenario, the retailers need a solution that helps them understand and decode the demand patterns at each store location for each SKU so that replenishment plans can be optimized to prevent stock imbalances and capital loss.

This requires forecasting and replenishment at a granular level, think SKU, and store locations; meaning, the computational requirement is massive.

On the other hand, the legacy systems and inventory planning tools work at the Category or sub-category level for each location. So, they are essentially treating all the SKU types the same for all locations. Hence, the demand for chocolate cookies, large pack, sold at one location, is modeled similarly to the demand for coconut cookies, small pack, being sold at another store.

This disconnect creates a huge problem by skewing the demand signals and limiting the optimization efficacy to a standard, one-size-fits-all approach.

It stems from the fact that traditional tools work with only a set of demand modeling methods and lack the sophistication and granularity to achieve robust, agile, and scalable replenishment planning at scale with hyperlocal precision.

So, if retailers are working with an infrastructure that is not tuned or built for the complexity and scale of food and grocery retail, then the results would definitely be below par.

Decoding Demand, and Overcoming Uncertainty in Food & Grocery Retail: What WORKS?

Before we take a deeper dive, here is a fact worth mulling over:

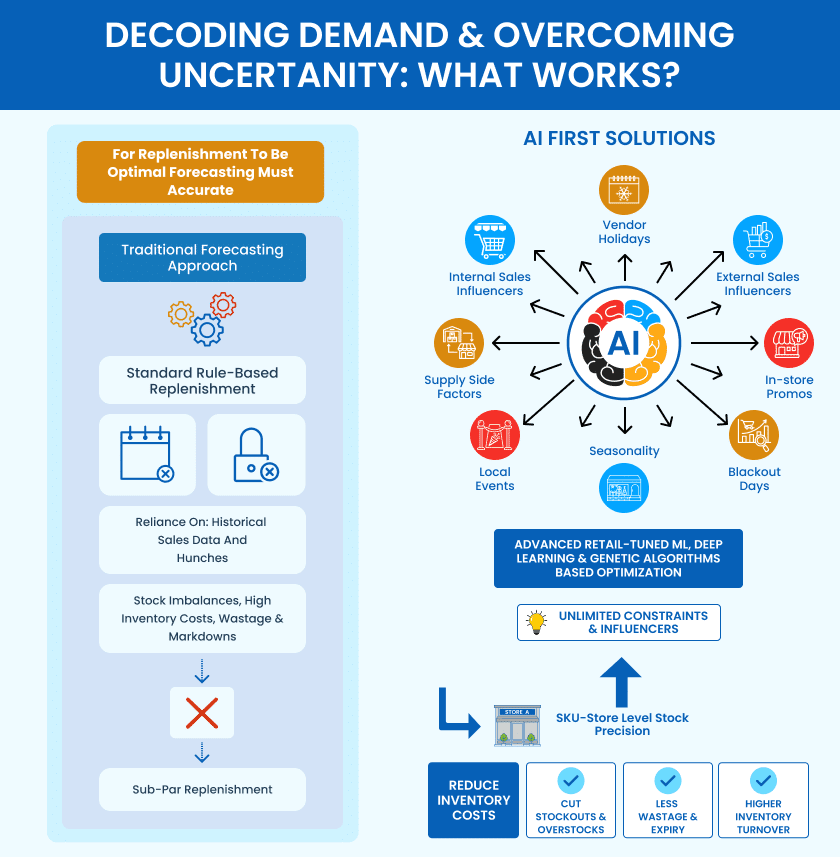

For replenishment to be optimal, forecasting must be accurate.

Traditionally, demand planning and replenishment are disparate processes, and lack the modeling sophistication to factor in the nuances that are unique to the food and grocery segment.

This is exactly where the strength of AI-first solutions lies.

AI-first solutions coupled with advanced retail-tuned ML, deep learning, and genetic optimization algorithms have this inherent capability to model not only the nuances of the food and grocery retail, but also to add an unlimited number of constraints or influencers.

Further, the AI/ML-led solutions have unmatched computational strength, enabling retailers to optimize the replenishment at the SKU-store level for hyperlocal precision. Hence, they can reduce inventory while cutting stockouts, wastage, and expiry.

This means retailers no longer have to stick to historical sales data, seasonal data, and manual adjustments based on hunches while planning for the upcoming holiday season or weekdays. They can factor in all kinds of external and internal sales and demand influencers, vendor holidays, and supply-side factors like minimum order quantities and more, and that too at scale.

Let’s take a look at how this happens.

Optimizing Food & Grocery Inventory With AI-led Auto-Replenishment Built for Hyperlocal Precision Delivered at Scale

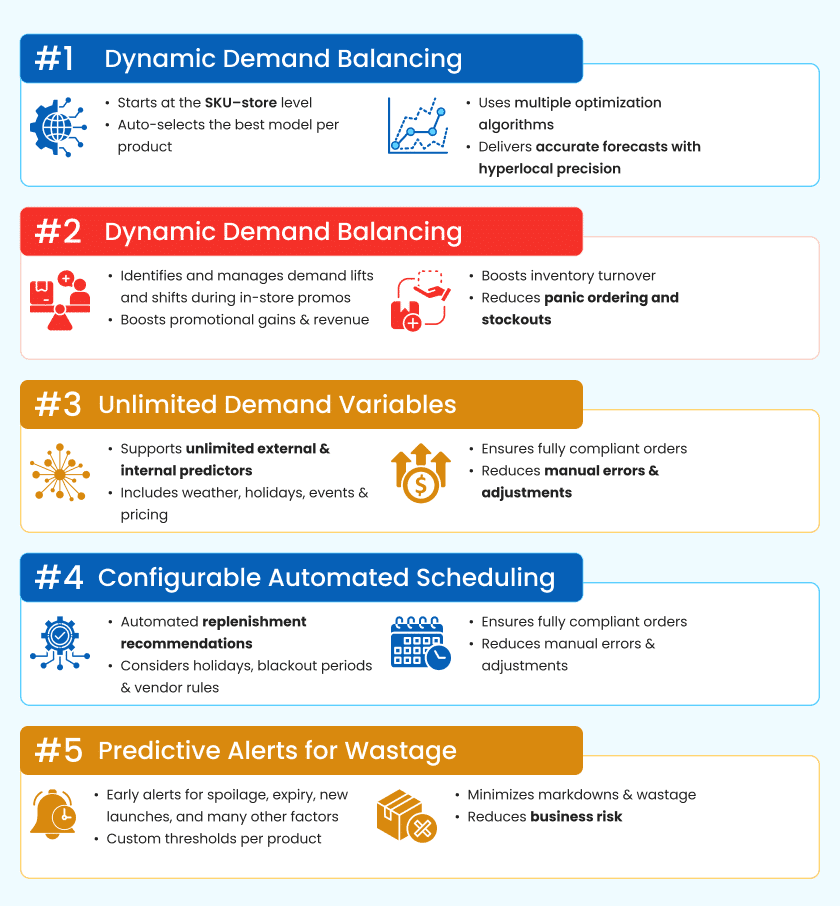

#1 – Modeling Sophistication

AI-first solutions start at the SKU level and come with multiple optimization algorithms. They automatically select the most optimal algorithm for each product-store combination, using automatic or user-defined model selection criteria. Plus, they incorporate unlimited demand predictors, delivering highly accurate, hyperlocal forecasts.

Ultimately, retailers can get accurate forecasts for millions of SKU-store combinations without compromising speed, accuracy, or coverage.

#2 – Dynamic Demand Balancing

One critical drawback of traditional demand planning and replenishment tools is their inability to identify and manage the demand fluctuations or cannibalization during in-store promotions. This costs retailers as much as 17% of their promotional revenue, causing either stockouts or overstock.

AI/ML-led solutions enable retailers with dynamic demand balancing by anticipating the promo-effects well ahead of time and optimizing the replenishment recommendations automatically. Hence, the order plans ensure that more amount of quick-selling items are ordered and products with declining demand due to promotions are ordered less.

This keeps the inventory distortions at bay while preventing the margin loss from demand fluctuations during promotions.

#3 – Unlimited Demand Variables

Another powerful feature of AI-led demand forecasting and auto-replenishment solutions is their ability to allow users to add an unlimited number of demand variables. These solutions treat every influencer as a predictor variable, and factor in everything, ranging from weather, holidays, seasons, local events, to promotions, discounts, and many more such factors to offer unparalleled accuracy in demand forecasting.

Further, the users can choose the set of variables for each SKU and store combination, thereby unlocking never-before-seen accuracy for each store location. The ability to do so without feature-level coding or engineering requirements is another fantastic advantage of AI-first auto-replenishment solutions.

#4 – Configurable Automated Scheduling

Food and grocery retail order scheduling is particularly complex owing to its scale and diversity of SKUs. While traditional tools offer limited or negligible scheduling features for optimal ordering, AI-first solutions save time and help avoid errors by automating complex order scheduling.

They offer configurable automated scheduling capabilities that seamlessly incorporate all order placement, acceptance, and delivery restrictions, ensuring replenishment plans always comply with holidays and blackout periods, eliminating manual adjustments.

#5 – Predictive Alerts for Proactive Wastage & Expiration Management

Food and grocery retail inventory is vulnerable to markdowns stemming from high vulnerability to wastage, spoilage, and expiry. The problem becomes even more challenging while dealing with millions of SKU-store combinations to work with.

AI-first solutions inherently curb this with predictive alerting capabilities that can be configured at the product level with user-defined thresholds. The predictive alerts accurately notify potential wastages and expirations, helping retailers to take proactive actions, with time to spare.

Hence, retailers can act early to reduce spoilage, protect profits, and maintain shelf freshness.

With planning and optimizing capabilities delivering hyperlocal precision at scale, AI-first solutions definitely emerge as the most reliable and the best way forward for food and grocery retailers.

in Sweden from 7 - 8 October 2025. Pre-book a meeting to connect with our

product experts.

in Sweden from 7 - 8 October 2025. Pre-book a meeting to connect with our

product experts.