According to Statista, global inventory distortions cost retailers as much as USD 580 million. Also, the value of grocery retail items going out of stock exceeds USD 500 million. Add increasing fulfillment costs for merchants, longer lead times, demand for better assortment across multiple categories, and breakneck competition to the mix and the retailers end up with a Pandora’s Box in their hands.

While technology-driven inventory planning and management systems are replacing manual and traditional planning frameworks, the overall inventory costs are rising and stock optimization still remains a critical challenge for profitability in the retail sector. This is mainly due to the highly nuanced nature of the various segments such as microtrends and huge seasonality in the health, beauty, and wellness segment, rich assortment and variety constraints in the convenience sector, and demand-based planning in grocery.

However, the nuances are not limited to these factors only. The overlapping of multiple sales influencers, sales and promotional events, holidays, seasons, social media trends, weather, and the deep impact of macro and micro-geographic-level trends/activities make demand anticipation hard and inventory optimisation even harder.

How can retailers optimize inventory with granular precision at the SKU or store level, and what makes optimization of retail inventory so important? What are the various benefits of retail inventory optimization and how to optimize inventory for different retail segments? Finally, is inventory planning different from inventory optimization?

Below, we explore the answers to all these questions at length and discover the benefits of optimizing inventory in an industry-wise manner.

What Is Retail Inventory Optimization?

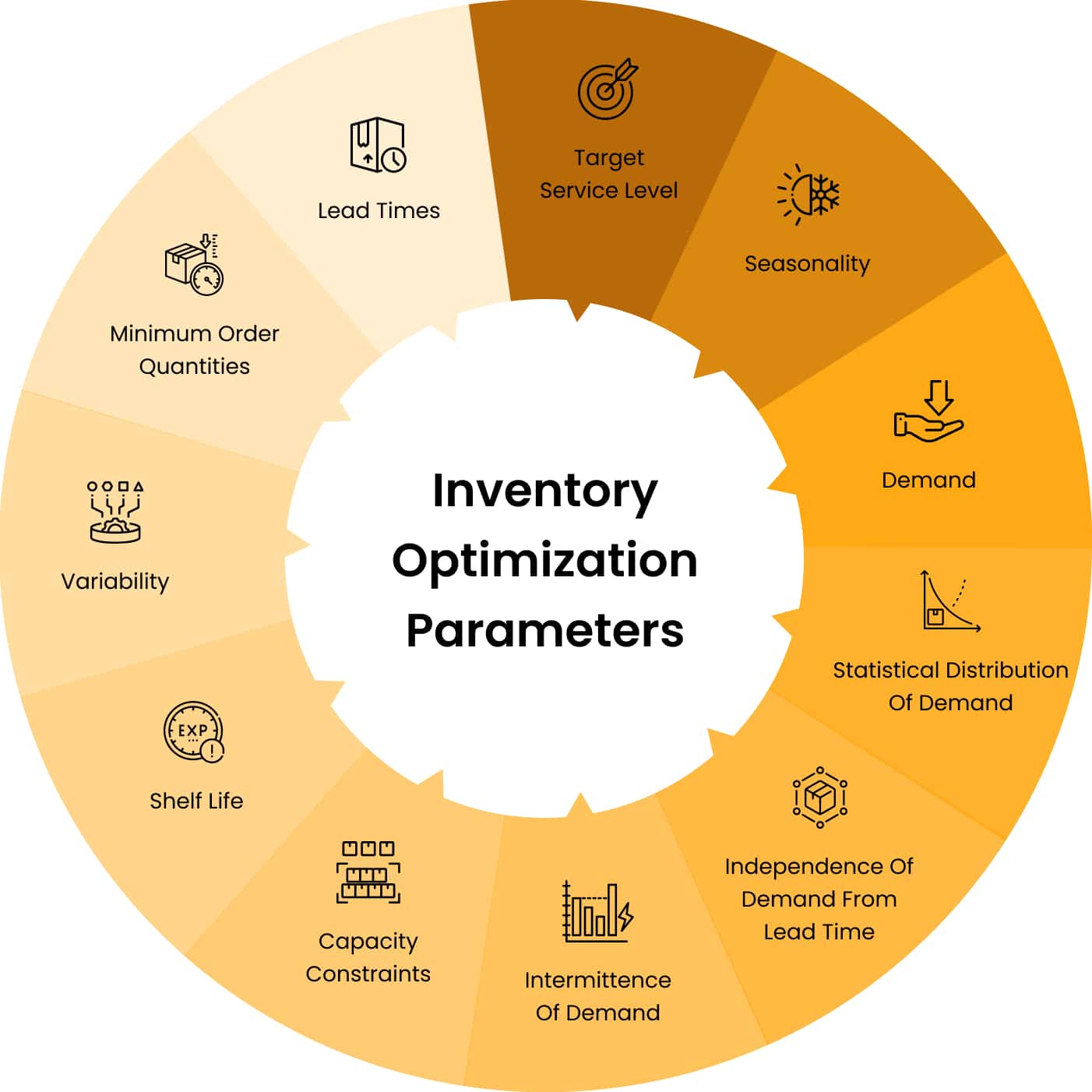

Optimising inventory means ensuring that the right stock is present in the right quantities at the right location and time, such that the wastage, spoilage, inventory holding costs, and stock issues are minimized without affecting the shelf availability. It also involves planning stock for promotional and sales events while considering the in-store cannibalization and inter-SKU demand shifts and lifts to keep the revenue intact.

Inventory cannot be optimized at such a granular level either manually or with traditional inventory management solutions. Optimized inventory is achieved with the help of intelligent inventory optimization software solutions that consider historical demand patterns, custom sales influencing parameters, and demand planning capabilities.

Why Is Inventory Optimization Important?

Inventory optimization empowers retailers to adapt to demand patterns and supply chain dynamics at an ultra-granular level effortlessly and quickly. They can anticipate the demand in real-time and get automatic updates for just-in-time inventory (JIT inventory), days of stock, out-of-stock, and other configurable inventory events.

Inventory stock optimization allows retailers to quickly adjust the stock replenishment or order plans based on automatically generated forecasts while incorporating the custom rules and settings for specific stores, zones, regions, and geographies. The retailers no longer need to manually adjust for increased demand in specific SKUs or categories and they can easily visualize the inter-category/SKU and intra-category/SKU interplay at a highly granular level.

Another excellent advantage of inventory optimisation is the ability to adapt to the supply side disruptions in an agile and robust manner. AI and ML-driven inventory optimization solutions come with built-in self-learning capabilities to model variations in lead times, safety stock, fill rates, pending orders, and more to ensure optimal stock across the entire value chain.

Finally, the most critical benefit of stock optimization is the ability to outsmart the sales and profit-crushing factors stemming from incomplete or faulty data analytics (for the org-level data as well as competitor and market data).

How Is Inventory Optimization Different From Inventory Planning?

While the emergence of cloud-based and continuously-developed software solutions is constantly blurring the lines between capability-based software platforms, understanding the distinction between operational systems is critical for choosing the right platform, especially in retail.

While inventory planning and inventory optimization are related, they are conceptually distinct. Inventory planning focuses on ensuring that there is sufficient inventory to meet customer demand, keeping stockouts and overstocks at bay, and also involves stock management capabilities, which have been a major offering in ITSM software solutions for many years now.

On the other hand, the core focus of inventory optimization is to maximize inventory replenishment efficiency while reducing costs and wastage and increasing shelf availability. Inventory optimization solutions offer many advanced capabilities to users that allow for custom adjustments in inventory planning, demand forecasting, and supply-side disruption management.

In easier words, it can be considered inventory management optimization and is the next step that retailers should take for better stock efficiency, lower carrying or holding costs, and reduced risks of out-of-stock and overstock events. The retailers can effectively cut the wastage and manage in-store cannibalization to achieve higher profit margins.

Exploring the Benefits of Inventory Optimization – Industry-Wise Overview

Grocery Retail

Grocery Retail

Studies reveal that 40% of retailers cancel at least one in ten orders due to inaccurate inventory data. Further, as many as 60% of retailers have less than 80% inventory accuracy and face data challenges.

The grocery retail sector is prone to wastage, inefficient inventory planning, inaccurate forecasting, and strongly fluctuating customer demand. This calls for effective demand planning and optimizing inventory based on data-driven insights.

Benefits of Inventory Optimization in Grocery Retail

- Data-Driven Decision Making

Inventory optimization software solutions can effortlessly integrate data across all functions to draw actionable insights for inventory planning. This ensures accurate and responsive inventory management aligned with real-time customer demand. - Accurate Demand Planning

Research reveals that AI-powered forecasting can reduce supply chain errors by 30 to 50%, shrinking lost sales by 65% and warehousing costs by 10 to 40%.

Inventory optimizing software comes with a built-in AI-driven forecasting engine that generates highly accurate forecasts while accounting for highly granular demand patterns and other sales influencers down to the SKU and location level.

They streamline supplier communication and collaboration, reduce lead times, and improve fulfillment, all the while reducing stock issues, and inventory holding costs and boosting shelf availability.

- Effective Promotions

Inter-SKU effects can wipe out as much as 17% of the extra sales volume that is supposed to be generated by promotions.

This is mainly because manual or traditional inventory planning fails to identify the effect of sales on different products and product categories.

On the other hand, ML-driven inventory optimization balances demand at the SKU level to ensure minimal competition via robust visualization of demand shifts and lifts across all categories and SKUs. This helps minimize inventory holding, stockouts, overstock, etc., and keeps the profits intact across all categories.

- Minimized Wastage and Spoilage Optimizing inventory in grocery retail enables retailers to anticipate customer demand accurately for specific items in extremely challenging categories, such as fresh and ultra-fresh. They can get automated insights for any disruptions, demand shifts, etc., and reduce their sales and revenue loss due to spoilage and wastage.

ML and AI inventory optimization can help retailers to:

- Reduce Inventory Cost by 10%

- Reduce Out-of-Stock Instances by 75%

- Reduce Wastage by 10-30%

- Increase Shelf Availability by 99%

Case Study

A Leading Grocery Retailer in South East Asia Slashes Stockouts by 63% and Inventory Costs by $ 1.5 Million

Convenience Store Retail

Convenience Store Retail

The convenience store or C-store industry faces unique inventory optimization challenges, ranging from fluctuating customer demands to distinct buying preferences in specific segments. The factors influencing demand patterns vary from the time of day, local events, seasonality, and microtrends to geography or area-specific factors.

Further, the introduction of mobile apps and ultra-fresh categories, such as food service, has added to the supply chain challenges and retailers find it extremely hard to make adjustments on the go. This is where AI-based capabilities in demand planning and inventory replenishment come into play.

Benefits of Inventory Optimization in Convenience Store Retail

- Multivariate Demand Planning

AI-driven inventory optimization software solutions come with advanced functionalities such as multivariate demand forecasting. Thus, retailers can generate highly accurate forecasts while factoring in seasonal changes, local events, weather patterns, lead times, storage space, and more at an ultra-granular level for each channel, store, and category.Incorporating external sales influencers in inventory planning can boost forecast accuracy by 10 to 15% and can drive cost savings across transportation, obsolescence, and inventory.

- Dynamic Product Mix

When asked what makes their C-store shopping experience great, 42% of customers responded with “having the right stock” and 28% of them went with “variety”.

While having a rich assortment is a critical must-have for C-store retailers, it can easily balloon the inventory costs and dent the revenue. Fast-moving products, short shelf life, constant demand for variety, and limited storage space make it hard for C-store retailers to offer a rich assortment.

C-store inventory optimization software leverages the built-in intelligence of AI and ML algorithms to comprehend demand and supply fluctuations at the minutest product and location levels. Retailers can generate highly precise order plans every time for each location without compromising the shopping experience and bottom lines.

- Managing Unpredictable Demand Patterns

As many as 88% of customers consider the experience provided by a brand to be as valuable as its products or services.

In C-store retail, the product lifecycle is short and inventory is quickly moving. Coupled with highly fluctuating demand patterns, it makes a complex puzzle beyond the reach of traditional inventory planning systems.

Intelligent inventory optimization software can easily overcome these bottlenecks by factoring in diverse, complex, and granular sales influencers for C-store retail. With advanced retail data modeling and intelligent demand forecasting, they can optimize inventory for specific locations, stores, channels, products, etc. while reducing inventory costs and improving accurate shelf availability.

- Competition from Quick Delivery Services

Armed with the ability to get things delivered to their doorsteps in less than an hour has left a significant dent in the C-store market. Hence, anticipating demand intelligently and ensuring delightful customer experiences has become even more important for convenience retailers.

AI and ML-driven inventory optimization software leverages different techniques for different business use cases and allows users to choose custom parameters for optimizing inventory at the product-location level. Offering the right products at the right time without leaving the shelves overflowing or empty helps boost revenue as well.

- Chaos-Free Promotions

Running effective promotions in convenience retail is challenging because of the large number of suppliers, short product lifecycles, quick new product introductions, etc. Further, the sales are affected by the local parameters and the inventory planning solutions lack the ability to analyze data from multiple sources keeping the core sales and demand patterns in mind.

On the other hand, the software for inventory optimization in convenience store retail takes multiple datasets as input, such as historical sales and promotional data, seasonal trends, and external & internal sales data. The software shows effects on the demand for specific products due to promotions down to the SKU, across every different product location.

Case Study

A Major US-based Convenience Store Retailer Takes Its Supplier Collaboration to the Next Level

Health, Beauty & Wellness

Health, Beauty & Wellness

Health, beauty, and wellness is another challenging retail segment and is an umbrella term for different emerging aspects of pharmacy and personal care. The segment suffers from intense competition, significant obsolescence, seasonality, higher inventory holding costs, and sudden market shifts due to new products and social media trends.

More than 50% of consumers use multiple brands for products like hair, skincare, and fragrance, making accurate demand forecasting difficult.

- High Inventory Costs

The health, beauty, and wellness retail has high-bulk, high-value product categories, making the inventory costs significantly higher than the other segments. Hence, any slips in demand forecasting and replenishment planning can erode the bottom lines and leave retailers with reduced finances for further sourcing.

AI/ML-driven inventory optimization software solutions tackle the root cause of the problem with highly accurate forecasting and precise order planning across different product locations. They can analyze real-time data and demand patterns at an ultra-granular level, such as channel, store, category, SKU, and more.

- Adaptive Replenishment

The health and beauty retail segment experiences rapid trend shifts and demand fluctuations, and unpredictable factors such as influencer-led marketing and product critique can render an entire category obsolete.

This volatility makes inventory planning particularly challenging, taking down accuracy rates to anywhere between 30% and 50%, mainly because the planning systems are unable to anticipate and adapt to such disruptions.

Optimizing inventory with adaptive self-learning models enables retailers to model variations in key supply-side metrics, such as lead times, pending orders, fill rates, safety stock, and more. Hence, retailers can effortlessly manage disruptions and ensure business continuity even during demand shifts or new product introductions.

- Managing Seasonality

Health, beauty, and wellness consumers across the globe are using different brands for different seasons and more than two or three products from different brands at a time. Thus, seasonality has a huge impact on the overall inventory planning.

Smart inventory optimization software incorporates historical sales data, upcoming trends, available stock, and highly granular sales influencers (external as well as internal factors) for specific stores, channels, locations, categories, and more, to manage seasonal and hyperlocal variations in demand.

- New Product Introductions

Nearly 50% of US beauty shoppers buy new products based on online feedback from others but poor inventory management can lead to a 25% loss in potential sales due to out-of-stock events.

Automated inventory optimization platforms utilize attribute-based and hierarchical forecasting for similar product attributes and higher-level category trend analysis. This ensures better stock availability, precise anticipation of customer needs, and quick adjustments to demand shifts at the hyperlocal level.

Case Study

A Leading Pan-Asian Health, Beauty, and Wellness Retailer Reduces OOS by 60% and Unlocks a 62% Increase in Inventory Turnover

How Can Algonomy Help?

Algonomy offers a highly advanced Machine Learning-driven inventory optimization software solution – Order Right, with a built-in demand forecasting engine running on AI and advanced data analytics.

Thus, retailers from all segments of the retail industry can plan the inventory, and demand, and take care of supply-side disruptions, all from a single dashboard interface. Order Right comes with automatic outlier detection and ensemble algorithms, self-defines the best-fit criteria, and allows the users to configure them. It offers custom algorithm selection and allows retailers to add or drop demand predictors and set their priorities for extremely precise forecasting.

Order Right leverages hierarchical forecasting to overcome retail data noise and generate highly accurate forecasts. As the inventory replenishment is built on top of highly accurate demand forecasting, and the models are constantly trained on historical data, trends, and demand patterns, the retailers are able to optimize the inventory in a strategic and efficient manner, thereby unlocking multiple business benefits, including:

- 10% Reduction in Inventory Costs

- 75% Reduction in Out-of-Stocks

- 10-30% Reduction in Wastage

- 99% Shelf-Availability

For more information about how Order Right optimizes inventory while tackling core planning issues such as inter-SKU effects or in-store cannibalization, supply side disruptions, and more, please get in touch with our experts for a personalized free demo session today!

in Sweden from 7 - 8 October 2025. Pre-book a meeting to connect with our

product experts.

in Sweden from 7 - 8 October 2025. Pre-book a meeting to connect with our

product experts.