AI-Led Replenishment Built for Convenience Store Retail

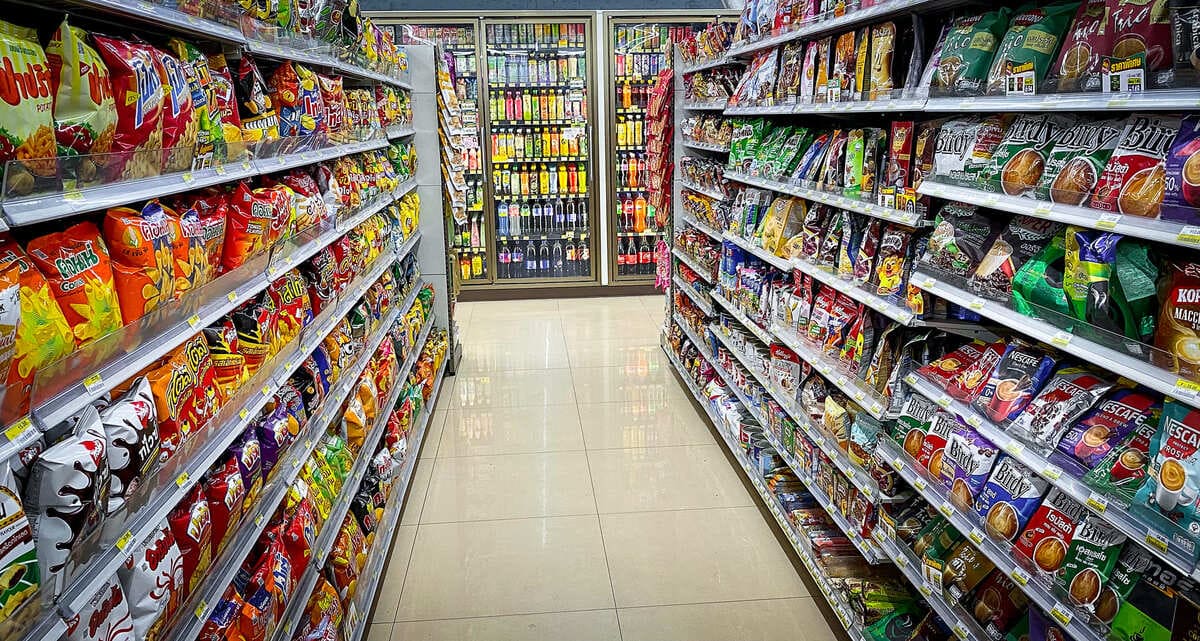

Optimize your convenience store inventory with automated replenishment recommendations. Reduce stockouts, inventory investments, and spoilage due to overstocks with hyperlocal precision.

Our Customers

Leading retailers and brands across the globe have optimized their supply chain and merchandise planning and execution with Algonomy.

Improved Business Outcomes with AI-Led Replenishment for Convenience Retail

60%

60%Reduction in

Out-of-Stock Instances

20%

20%Reduction in

Inventory Investments

20%

20%Improvement in

Revenue & Profitability for RTE Category

25%

25%Improvement in

Operational Efficiencies

Why Convenience Retail Needs A Replenishment Strategy Reset?

Lack of Space-Aware Inventory Optimization

Traditional inventory systems struggle to align convenience store replenishment with the tight shelf and storage constraints, resulting in frequent stockouts or excess inventory.

Spoilage from Poor Forecasting in the RTE Category

C-stores stock large volumes of ready-to-eat items with volatile, location-specific demand. Inaccurate forecasts lead to overstocking and spoilage, eroding margins and profitability.

Need for Planogram Adherence

Adhering to all the planogram-imposed rules and constraints makes the replenishment planning process cumbersome and needs manual intervention.

Warehouse-Level Inventory Optimization

C-Stores rely heavily on warehouse or distribution centre inventory, which means maintaining optimal stock levels at those locations is critical to ensuring consistent store supply and preventing stockouts.

Inefficient Allocation of High-Demand Key Value Items

Poor allocation of high-demand key value items leads to frequent stockouts, impacting revenue and customer trust.

Automatically Optimize C-Store Inventory Across All Locations to Maximize Availability and Minimize Waste

Order Right helps convenience retailers boost profitability, reduce waste, and maximize shelf availability through AI-powered, hyperlocal forecasting and automated replenishment tailored to limited space and fast-moving assortments.

Auto-Replenishment for Tight Shelf Space

Predict demand accurately at the SKU-location level and get AI-generated automatic replenishment recommendations that fit your shelf space perfectly. Improve shelf-availability while factoring in store-specific demand influencers and reducing inventory investments.

Modeling Configurations to Reduce Spoilage in RTE

Protect margins by reducing spoilage due to overstocking of ready-to-eat inventory without compromising availability. With advanced built-in configurations, such as over-forecasting penalties, Order Right effectively curbs spoilage due to overstocks.

Built-in Planogram Adherence

Eliminate the need to manually tweak orders for planogram compliance. Order Right automatically incorporates key planogram constraints, such as minimum display quantities, maximum shelf capacity, promotional display requirements, etc., for each location.

Holistic Replenishment Planning

Get auto-replenishment recommendations for all types of orders: Direct Store Orders, Stock Transfer Orders, and Warehouse Orders. Order Right ensures optimal inventory levels at all locations and helps improve replenishment planning holistically.

Automatic Optimal Stock Allocation Mode

Optimize high-demand key value item allocation for all store locations. If the warehouse runs low, Order Right automatically allocates the limited high-demand items based on configurable allocation methods for equitable or store rank-based allocation.

Explore Client Success Stories

Helpful Resources

Explore our resources, case studies, infographics, eBooks, and more for a deeper understanding.

Take your replenishment planning to the next level with Order Right.

-

60%

60%Reduction in

Out-of-Stock Instances -

20%

20%Reduction in

Inventory Investments -

20%

20%Improvement in

Revenue & Profitability for RTE Category -

25%

25%Improvement in

Operational Efficiencies

in Sweden from 7 - 8 October 2025. Pre-book a meeting to connect with our

product experts.

in Sweden from 7 - 8 October 2025. Pre-book a meeting to connect with our

product experts.