Middle Eastern Grocery Retailer Projects $60M Savings in Inventory Costs after Lowering Inventory Levels by 21%

Segment

Grocery

Objective

Achieve inventory reduction by 20% while maintaining availability above 90%

Product

Algonomy OrderRight

Outcomes

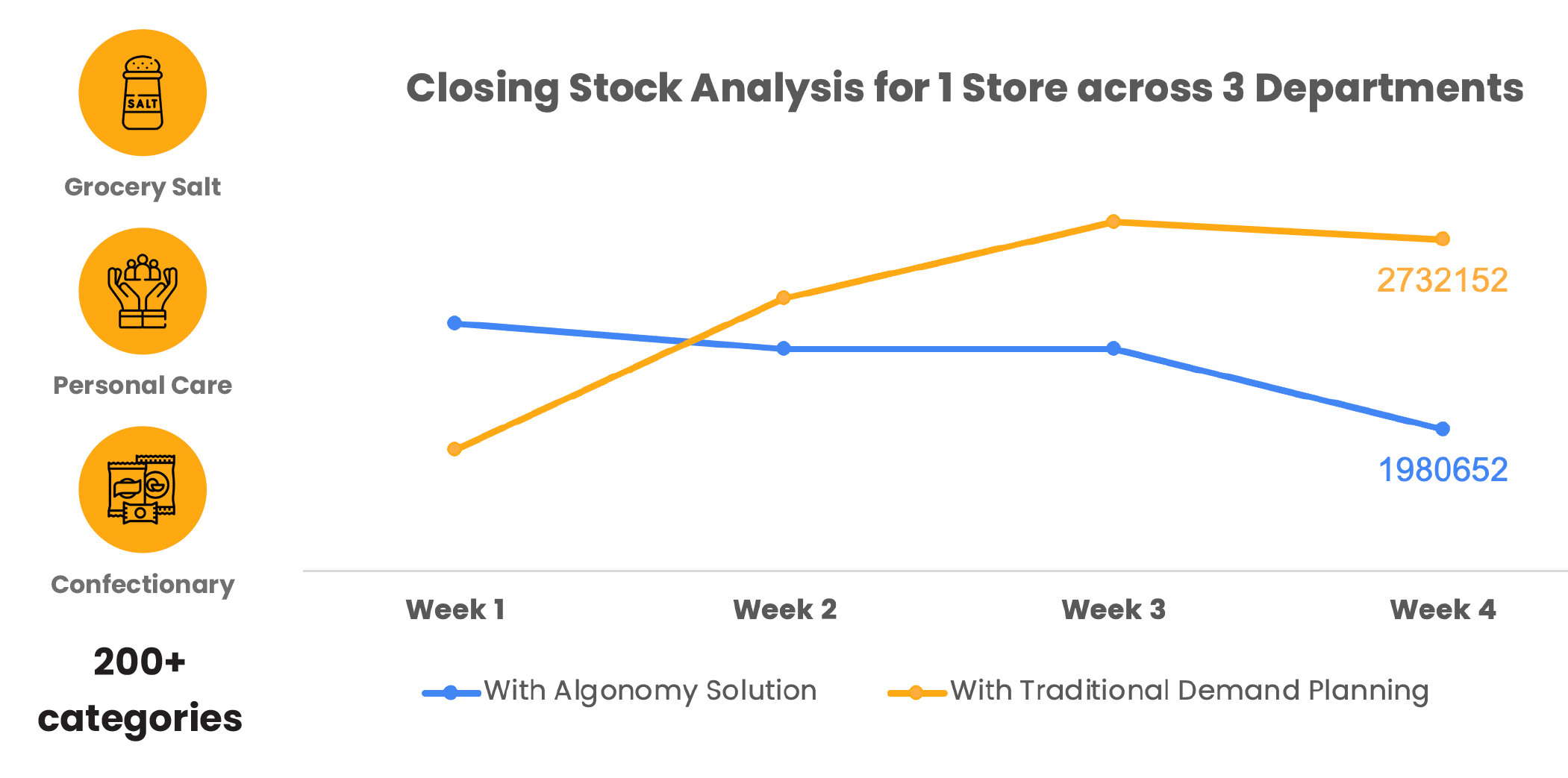

Reduction in inventory cost across 3 departments for the flagship store

Projected savings in inventory costs across 300+ stores

Reduction in out of stock instances with 90% shelf availability

Client Overview

Client is a major retailer based out of the Middle East. They are the pioneers in food wholesaling, grocery stores and malls. The company operates 300+ stores across multiple formats such as supermarkets and hypermarkets, convenience stores and wholesale outlets.

The client was looking for an enhanced demand forecasting and replenishment framework that could help them gauge accurate daily and monthly inventory requirements across stores. They set themselves a target of reducing inventory cost by 20% while not jeopardizing availability.

The client, already an existing user of traditional demand planning tools, strongly felt the need of a new replenishment framework that captures dynamic demand forces induced due to shifting consumer behavior and channel complexities while also cognizant of the as-is state and parameters of the supply chain. The client hoped that such a framework would help them cut down inventory cost without compromising on availability.

Want to achieve similar results for your grocery retail business?

Hyper-localized replenishment with retail-native AI

Algonomy’s demand forecasting and replenishment solution, part of its larger merchandise AI suite of solutions for retail, was the perfect match for the client’s requirement. It uses unique and retail-native handcrafted algorithms to achieve a near-perfect match between demand and supply. Its plug and play ability allows retailers to quickly realize return on investment without having to spend organizational resources in setting up or compromising on key business metrics.

As a part of its larger engagement the client wanted to focus on optimizing inventory cost across 3 departments for its marquee store located in the heart of the city. These 3 departments were – grocery salt, confectionery, and personal care. The combined count of categories under these departments was 200+. The choice of the departments was based on the fact that these departments had witnessed the most increase in inventory cost over the past year.

Algonomy’s demand forecasting and replenishment solution (Order Right) was configured and ready to use within two weeks of data integration.

With the help of Order Right, the client was able to automate and optimize replenishment schedules for 200+ categories across the 3 departments on a single platform without having to use multiple tools, systems and back of the hand calculations. As a result, the client was able to reduce inventory levels by 21% and also witnessed a 9% reduction in out of stock instances.

Order Right’s retail-native demand forecasting technique uses an ensemble of algorithms (2000+ unique algorithms including machine learning and deep learning algorithms) to predict demand for products.

These algorithms account for not just internal factors such as historical sales, promotions and inventory levels but also exogenous factors such as weather, festivals and events that affect demand. The outcome therefore is a more dynamically linked demand forecasting than traditional demand planning tools.

This predicted demand for products in conjunction with supply chain parameters such as lead time, minimum order quantity, fulfillment rate, etc. and category factors such as expiration date and shelf life are then fed into a a unique replenishment optimization engine to generate optimized replenishment schedules.

400+ retailers & brands across the world trust Algonomy to consistently deliver on their commerce KPIs

in Sweden from 7 - 8 October 2025. Pre-book a meeting to connect with our

product experts.

in Sweden from 7 - 8 October 2025. Pre-book a meeting to connect with our

product experts.