The Complete

Demand Planning Guide

in Retail

Strategies, Key Considerations,

and Best Practices

Retail demand patterns are no longer simply dictated by linear or seasonal trends. Fierce competition, social media engagement, and unpredictable consumer behavior can swing retail demand in a few days or even hours. Hence, retailers need to have a precise and agile approach to demand planning to avoid overstocks and stockouts.

Predictive demand planning software is one reliable solution that retailers can embrace to prevent inventory distortions and the multiple types of losses they incur from them. It helps retailers identify and navigate the demand shifts before they happen and replenish their stock proactively instead of reacting late.

In this detailed guide on demand planning and key software considerations, we discuss:

- What is demand planning?

- What does predictive demand planning mean, and how does it differ from traditional software?

- The role of data and data modeling methods in improving inventory forecast accuracy

- How can retailers benefit by switching from traditional demand planning software to predictive modeling software, and a step–by-step breakdown?

- Key strategies to enhance demand planning accuracy

- What to look for in a modern demand planning software?

- Why legacy demand planning software falls short — and how AI-led demand planning software overcomes those gaps?

- How Algonomy’s Order Right is the best software for adaptive, agile, predictive, and proactive demand planning with hyperlocal precision

Understanding Inventory Replenishment

Demand planning is the process of forecasting future customer demand for products to optimize inventory at all locations and streamline supply chain processes. It involves analysis of market trends, historical sales data, external and internal sales influencers like weather, local events, holidays, customer behavior, etc., to predict stock requirements and allocation.

Demand planning software in retail helps retailers prevent:

- Overstocks – eroding margins via markdowns and inventory spoilage

- Stockouts – empty shelves at the moment of need, lost sales, and negative customer experience

The result?

Replenishment decisions become smarter, and instances of stockout or overstocking are reduced due to better demand planning.

Traditionally, demand planning in retail is done via software that offers standard rule-based modeling logic that takes into account only a few specific sets of factors, such as historical data, standard holiday timelines, location, etc.

This prevents retailers from identifying the demand-purchase dynamics at every store location, meaning they allocate inventory similarly for all store locations. However, demand patterns vary across locations and types of SKUs and are influenced by diverse factors beyond the standard computation capabilities of traditional demand planning software.

What Is Predictive Demand Planning?

It utilizes AI/ML-based models for inventory demand planning and predictive analytics to anticipate when, what, and where consumers will make a purchase. The software anticipates future consumer demand in a predictive manner, so retailers can identify and navigate the demand and supply-related challenges well in advance, prevent stock distortions, such as stockouts and overstocks, and minimize wastage.

Such retail demand planning software runs on AI/ML computational abilities, enabling retailers to add multiple sales and demand influencers for each store location, improving the inventory forecast accuracy and supply efficiency.

The replenishment in the traditional demand forecasting solution is static, based on a few standard stocking windows and metrics. Plus, the insights are delivered in a prescriptive manner, meaning the software can’t factor in the dynamic demand changes in stock replenishment.

On the other hand, AI/ML-led demand forecasting software offers predictive alerts for replenishment based on futuristic demand planning.

How do Predictive and Traditional Demand Planning Differ?

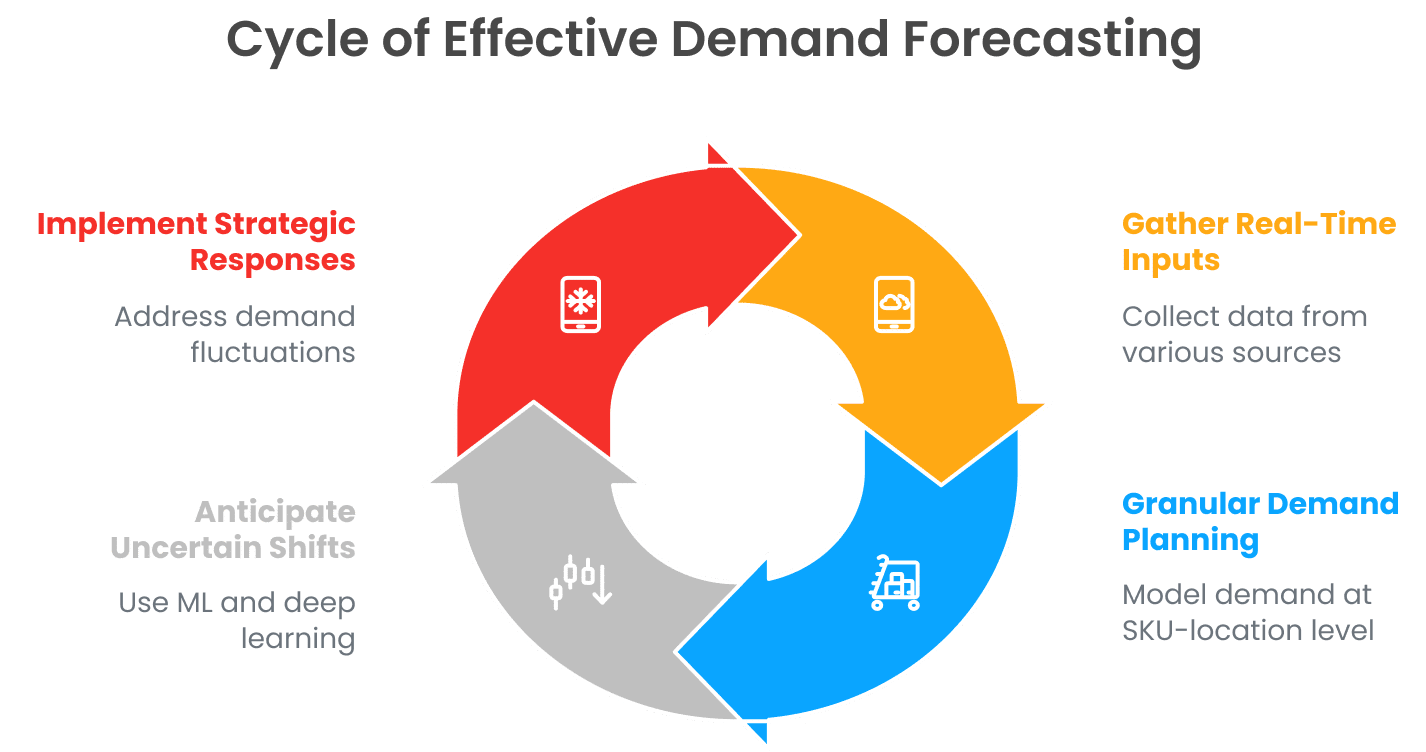

Unlike traditional inventory demand forecasting that relies on historical averages and rule-based logic, predictive demand planning anticipates real-world changes, be it sudden spikes in demand or a change in consumer behavior. The software achieves this via a combination of ML and deep learning algorithms, and hierarchical data models for demand planning, while factoring in all sorts of demand and sales influencers.

So, what makes such demand forecasting software so effective?

- Continuous adapting at all times, from real-time inputs such as weather, promotions, discount percentages, holidays, vendor events, etc.

- Granular level demand planning, which means the software models demand at the SKU-location level, ensures the inventory replenishment is precise and accurate at all times.

- Anticipation and adapting to uncertain shifts using ML and deep learning algorithms instead of general or fixed assumptions

- In-built strategic responses from the software, such as sudden demand declines and spikes driven by factors like weather and social media trends

How Accurate Is Predictive Demand Planning: How Does Data Quality Come Into the Picture?

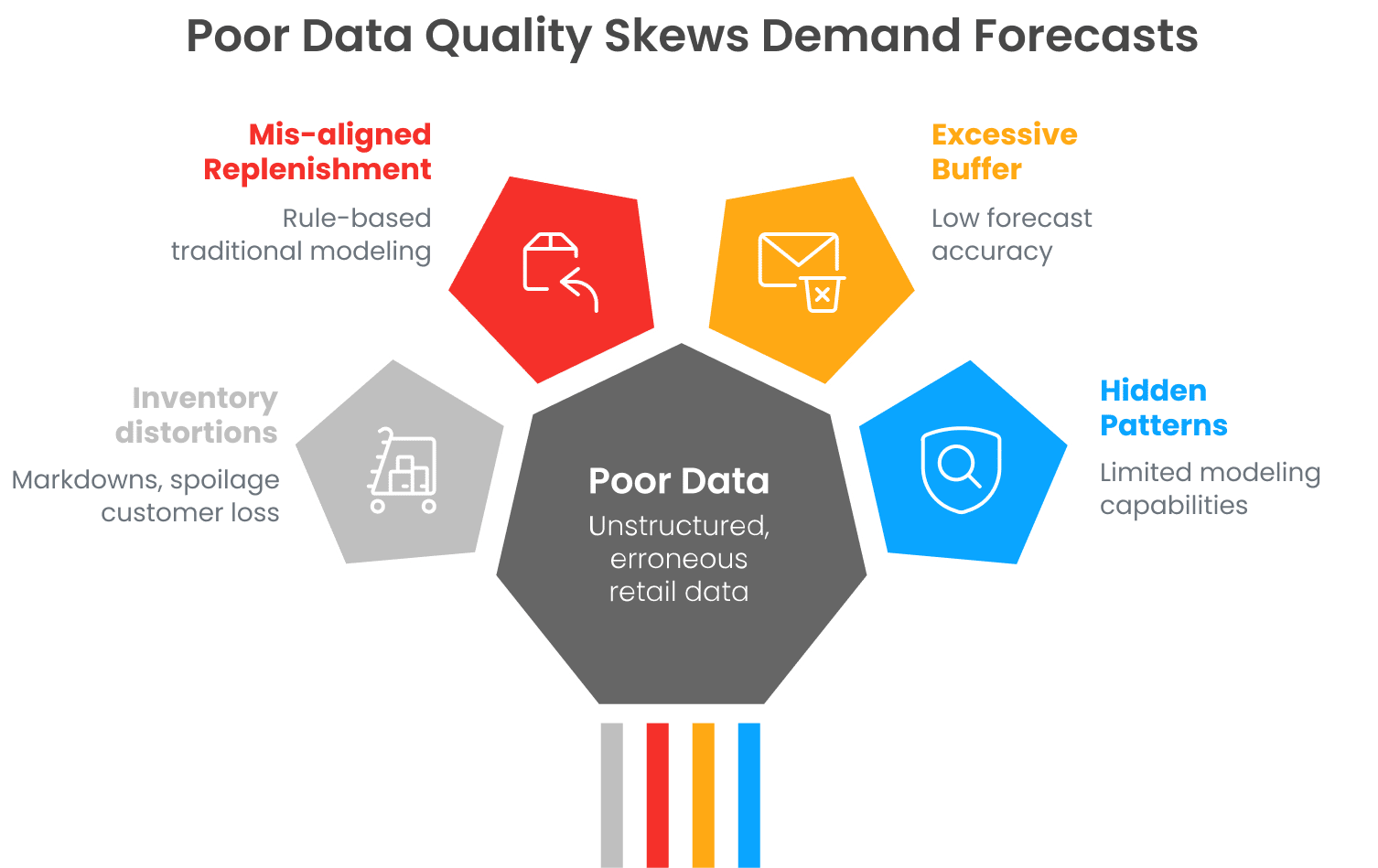

A core challenge in inventory demand forecasting is ensuring data quality and integrity. Retail businesses generate mountains of data, but often use traditional demand modeling software that functions in a siloed manner and lacks the data modeling sophistication, creating bottlenecks to accurate demand forecasting.

Further, the retail data is highly unstructured and riddled with gaps, noise, and erroneous data, too. Cleansing and prepping this data without overly correcting or losing relevant information while doing so is beyond the modeling capabilities of traditional demand planning software.

Using such data for inventory demand forecasting skews the forecasts, degrades the accuracy, and causes:

- Inventory distortions at multiple locations risk markdowns, spoilage, and customer loss

- Misaligned replenishment due to rule-based traditional modeling software

- Keeping more buffer inventory than needed due to low inventory forecast accuracy

Using such data for inventory demand forecasting skews the forecasts, degrades the accuracy, and causes:

- Inventory distortions at multiple locations risk markdowns, spoilage, and customer loss

- Misaligned replenishment due to rule-based traditional modeling software

- Keeping more buffer inventory than needed due to low inventory forecast accuracy

- True demand patterns are being hidden due to limited or negligible modeling capabilities in planning software for events such as parallel or seasonal promotions at scale.

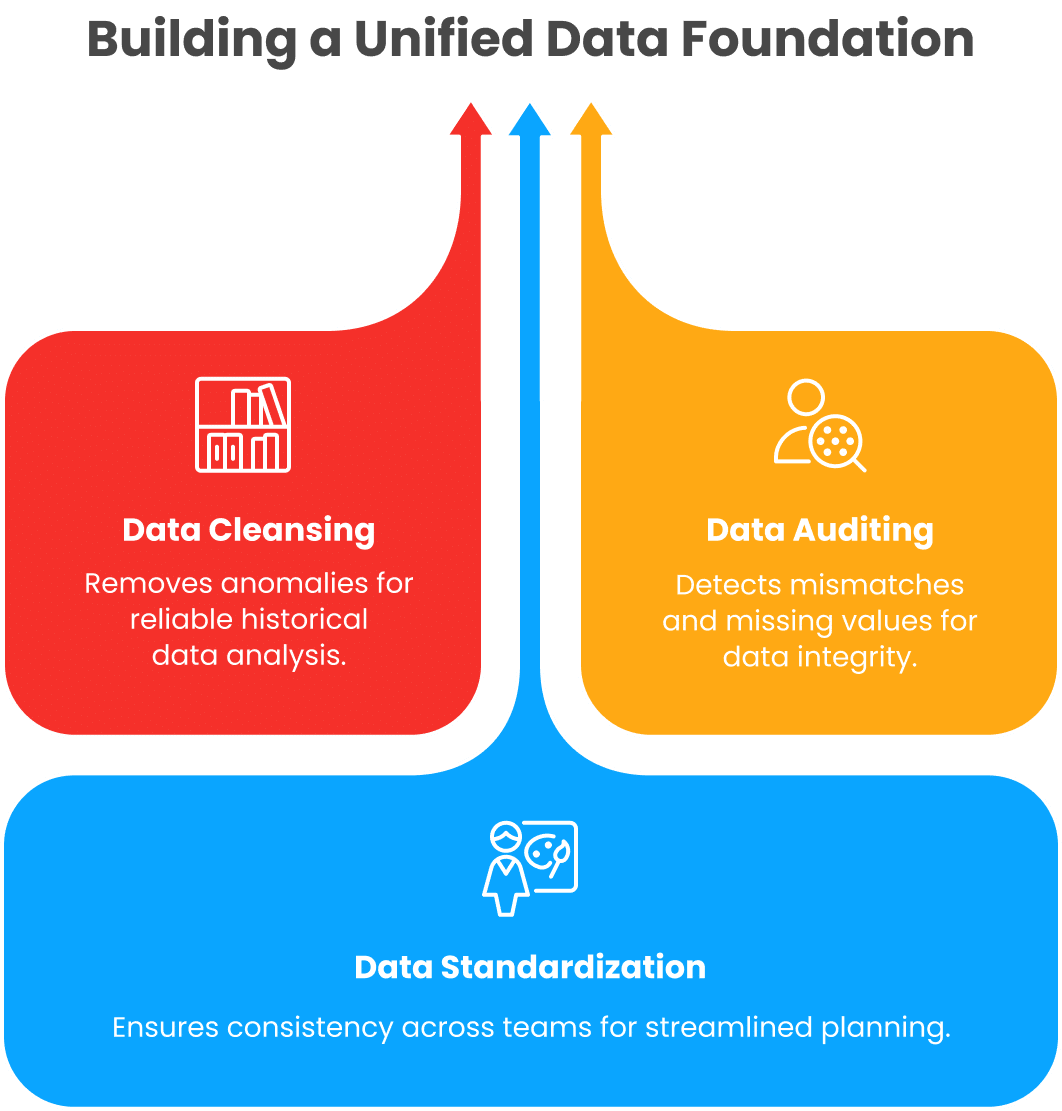

For retailers, accurate inventory demand planning requires a unified data foundation with high integrity. Hence, they need an inventory forecasting and replenishment software that offers:

- Cleansing of historical data to remove anomalies and duplications, such as returns and stockouts

- Automating data audits to detect mismatches in information and identifying missing values across platforms

- Standardizing software data inputs across teams to ensure data consistency and streamline demand planning

Hence, retailers should opt for demand planning software that comes with data optimization capabilities to get highly accurate inventory forecasts with hyperlocal precision.

Why Is Predictive Demand Planning Important for Retail?

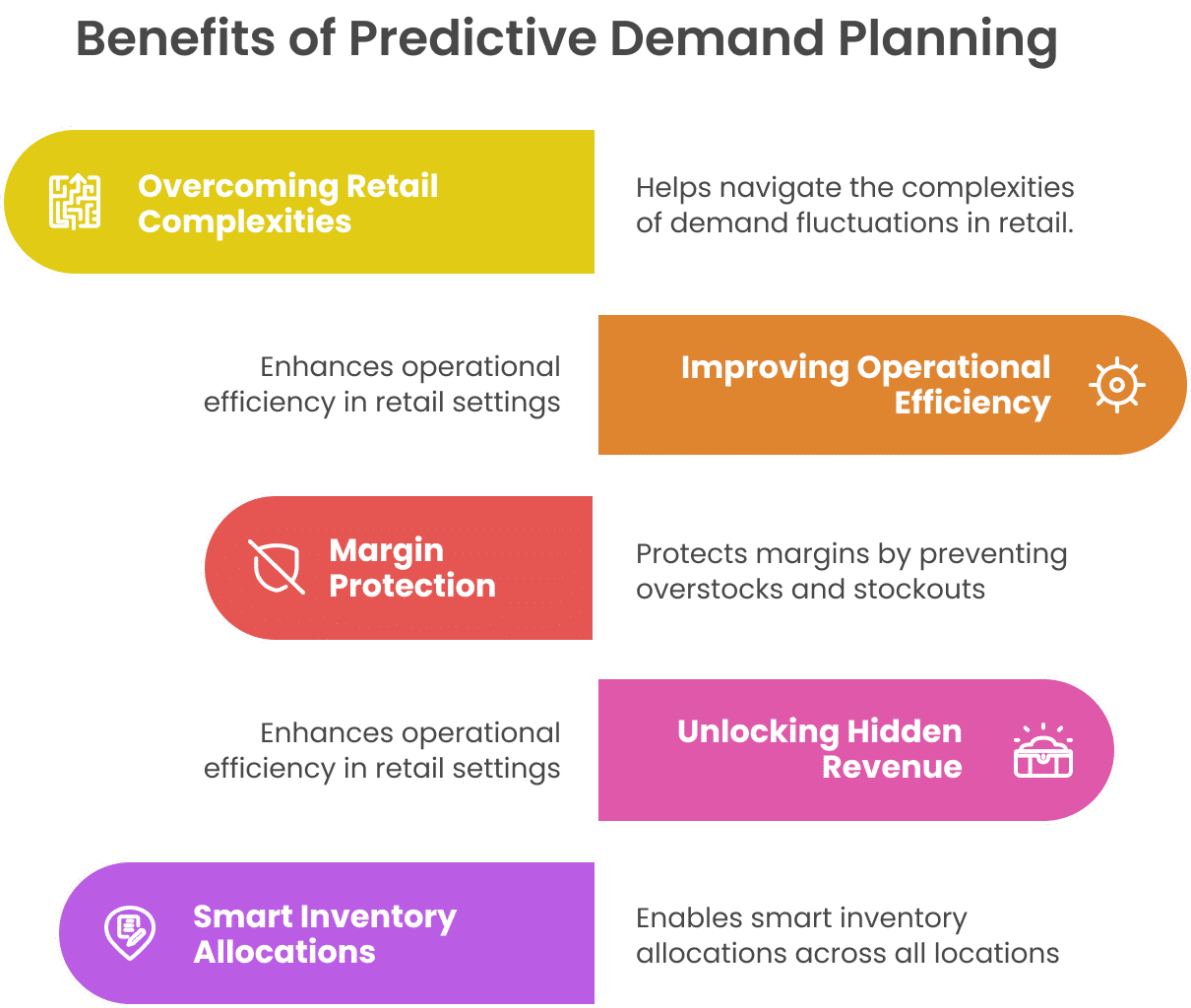

Overcoming Multi-format Retail Complexities

Nowadays, consumers shop from multiple platforms – websites, mobile apps, or your brick-and-mortar store. The real challenge here is demand forecasting for inventory levels across all these buyer channels.

With such demand planning software, retailers gain insights into channel-specific demands, which in turn allows them to maintain adequate inventory and efficient stock allocation.

Improving Operational Efficiency

With a data-driven approach to demand planning, manual intervention is no longer required in forecasting. Moreover, this method leads to much quicker decision-making and allows retail businesses to establish more agile strategies by simulating various scenarios.

Margin Protection from Overstocks and Stockouts

Stockouts directly translate to missed sales opportunities, and overstocks tie up capital in the form of excess inventory. With accurate demand planning and AI-led replenishment software, retailers are able to strike the right balance, optimizing order quantities and timing based on hyperlocal demand trends.

This helps lower inventory carrying costs, improve product availability, and reduce dependency on safety stock buffers.

Unlocking Hidden Revenue Across the Slow Movers

With AI and ML-driven demand planning, retailers can identify often overlooked sales potential, spotting micro-demand trends, enabling retailers to adapt replenishment strategies accordingly. With this demand planning software, niche or slow-moving items are stocked at the right quantity. Not too less, not too much.

Smart Inventory Allocations Across all Inventory Locations

AI-led demand planning provides granular inputs into demand trends, local events, customer preferences, etc., incorporated via real-time data. Armed with such software, retailers are now able to optimize inventory allocation and distribution across stores, bring down their transfer costs, ensure high fulfillment rates at the store level, and avoid understocking in high-velocity stores.

Why Does Traditional Demand Planning Software Fall Short?

Outdated One-Size-Fits-All Approach

Traditional demand planning software tends to apply static rules or historical averages across regions and inventory categories. They end up ignoring critical nuances such as evolving consumer behavior, varying store formats, and lead time variability.

Let’s say the urban store network witnesses an increase in demand for ready-to-eat SKUs. At the same time, Tier 2 stores favor goods with bulk-packaged formats.

Rigid Demand Planning Software Systems Cannot Adapt to Supply Chain Volatility

Legacy demand planning software often lacks the adaptability to model unexpected changes in lead times, input costs, or fill rates. Suppose the lead times for an imported product of frozen goods increase by 14 days, due to factors like port congestion. Traditional demand planning software platforms struggle or even fail to adjust reorder timelines, leading to stock gaps and missed sales opportunities.

Lack of Agility in Demand Forecasting

Unpredictable scenarios like price sensitivity or demand shocks make it challenging for a conventional demand forecasting solution to simulate varying business situations. Let’s say a 5% increase in price for an FMCG product leads to an unexpected drop in volume. The traditional demand planning software lacks the ability to test alternative pricing or model price elasticity.

Manual Interventions

Traditional software needs manual replenishment adjustments, such as adjusting the order plan for the upcoming holiday season based on the previous holiday season’s sales, which can lead to massive stock distortions. This hunch-based replenishment software can lead to costly mistakes such as capital lock-ins due to overstock and loss of revenue due to out-of-stock.

Further, the overstocked items can easily spoil or rot, or expire, causing double loss, while products that could have been sold are running out of stock. Such overstocks also spur markdowns, causing retailers to put products on sale, which further distorts the demand planning signals, creating a vicious cycle of stock imbalances that eats away at the bottom lines and profits.

With built-in capabilities for modeling demand fluctuations during in-store promotions, the AI-based demand planning software solution also prevents stock imbalances from promotions, keeping markdowns and wastage at bay.

Lack of Real-Time Demand Sensing

Traditionally, demand planning software solutions focus on historical data and past sales, ignoring live market signals. This often leaves retailers unprepared whenever fast-rising trends pop up or a specific product witnesses a sudden spike in demand.

Since traditional demand planning software is often anchored to the previous month’s data and forecasts demand at the inventory category level, they are incapable of planning replenishment for such sudden surges.

How Predictive Demand Planning Works for Retail: A Basic Overview

1 Data Collection

Predictive demand planning software solution gathers information from both internal and external sources, such as weather, market trends, CRM software platforms, e-commerce software, macroeconomic indicators, etc.

With such a diverse list of inputs for demand planning software, retailers can ensure a well-rounded overview of all the demand drivers.

2 Data Cleansing and Integration

The demand planning software offers an automatic cleansing and standardization process to remove inconsistencies and data duplication. Having clean and unified inventory and sales data as input for modeling software is core to building reliable demand forecasting models, with different departments aligned in overall business goals.

3 Demand Forecasting

AI-led software solution also implements ML (machine learning) algorithms to analyze historical and current data systematically to accurately predict future demand trends. Retailers can detect patterns, anomalies, or seasonal shifts in consumer behavior, leading to more dynamic, accurate, and reliable inventory demand forecasting.

4 Scenario Planning

AI-driven software for demand planning also simulates ‘What-If scenarios’, different possibilities help retailers estimate how variables (supply chain disruptions, competitors changing price rates) may impact future demand planning. Such planning software also reduces risk exposure by effectively cutting down stock imbalances and boosting inventory turnover.

5 Inventory Optimization

With inventory demand planning software outputs, retail teams can make data-informed decisions on procurement, replenishment, and inventory allocation. As a result, optimal stock levels are maintained across inventory locations while factoring in variables like lead times, storage capacity, and sales velocity.

It is important to note that the actual software workflow or the steps vary depending on the inventory forecasting software solution. Certain inventory demand planning software platforms offer capabilities like advanced clustering, automated data preprocessing, etc, while others could require more manual intervention.

How Does Accurate Inventory Demand Forecasting Directly Affect Revenue and Efficiency?

inventory forecast errors

Retailers can ensure better stock availability and minimize instances of overstocking

sales

Higher sales conversion and fewer missed opportunities

forecasting accuracy

and 5% slash in inventory on-hand

Strategies for Accurate Demand Planning

Understand Seasonal Trends, but Don’t Stop There

Retail inventory forecasting software for a long time has relied on spotting repeatable seasonal trends, like holiday surges, weekend uplift, etc. However, spotting seasonal trends alone is not enough in today’s landscape. Retailers need software that offers continuous recalibration, more specifically for SKUs that are affected by emerging inventory category bias or product trends.

Leveraging AI to Model Real-World Variables

Incorporating AI in an inventory demand forecasting solution can help go beyond mere averages and trend lines, with massive datasets being analyzed in near real-time. This enables retailers to stay upfront on demand signals.

The advanced inventory demand planning and auto-replenishment software solution allows retailers to factor in variables like holidays, vendor calendars, seasonality, etc., to ensure that replenishment is done around the real-world demand.

Demand-Sensing in Real-Time for Short-Term Accuracy

Demand sensing capabilities of inventory demand modeling software solution use real-time data and analytics, like weather trends or social media data, to fine-tune short-term inventory demand planning accuracy. For retail businesses, the sensing part of inventory demand planning is specifically helpful for:

- Perishable goods with short shelf lives

- Fast fashion or trend-driven SKUs

- High-velocity categories like snacks and beverages

As a result, retailers are subjected to fewer reactive transfers, quicker replenishment, and lower instances of inventory spoilage.

Key Considerations for Choosing the Best Inventory Demand Planning Software for Your Retail Business

Intuitive and Centralized Interface

Juggling among different software interfaces that make sense only to the technology-savvy people harms productivity. We recommend investing in a demand planning software that comes with an easy-to-use, highly navigable, and centralized dashboard-like interface.

Opt for software that comes with intuitive prompts and minimizes the time spent on figuring it out while maximizing operational efficiency.

Seamless Integration

Retail businesses generally operate on a complex network of software systems, from CRM, POS, ERP, to warehouse management software. Opt for demand planning software that can integrate seamlessly with existing inventory demand planning software, preventing silos and allowing for a real-time data flow across the entire value chain, encompassing warehouses, distribution centres, dark stores, stores, etc., ensuring synchronization of data points across sources.

Hyperlocal Demand Forecasting

Demand patterns vary from one store to another and from one SKU to another. Hence, investing in software for inventory demand planning that forecasts demand at the category or sub-category level prevents retailers from understanding the demand dynamics at the hyperlocal level.

This affects the overall inventory demand planning accuracy, and the stock imbalances prevail even after investing in an inventory replenishment planning software solution.

An inventory demand forecasting solution that comes with hyperlocal precision models for demand at the SKU-store location level, boosting accuracy and leaving no room for guesswork. Such granular inventory demand planning software helps improve shelf availability while reducing inventory investments and wastage simultaneously.

Auto-Replenishment and Inventory Planning

Always opt for inventory demand planning software solutions that dynamically adjust inventory levels based on real-time signals in demand, promotional campaigns, and supply chain hurdles. With negligible manual interventions in software logic, planners can focus more on strategic planning and decision-making.

The retailers can ensure quicker and more reliable replenishment with the auto-replenishment recommendations generated by the inventory planning software solutions in case of stockouts or during instances of sudden spikes in demand. The instances of over-ordering are reduced, since the software considers factors like excess stock or pending deliveries.

Promotional Planning to Prevent Cannibalization

Inventory demand planning software solutions must proactively calibrate replenishment by taking into account promotional lifts, avoiding cannibalization of similar items that may fall within the same inventory category.

Traditional inventory demand planning software can plan for demand lifts but overlooks the demand shifts that happen across all inventory categories and SKUs. Due to the demand shifts, the non-promoted items are overstocked while the promoted items run out of stock.

Hence, we recommend investing in an AI-driven inventory demand forecasting and auto-replenishment software solution like Order Right that comes with built-in promotional intelligence to optimize stock for all kinds of in-store promos.

Order Right: AI-Led Demand Planning and Auto-Replenishment with Hyperlocal Precision

Intuitive and Centralized Interface

Order Right, Algonomy’s AI-powered demand forecasting and replenishment software solution, enables retailers to align their inventory dynamically with the demand patterns at the SKU-store level for hyperlocal precision.

Built on top of AI-led hierarchical demand forecasting, Machine Learning, and deep learning ensemble algorithms, Order Right starts inventory and replenishment planning at the SKU level to model inventory demand accurately, even for the most challenging inventory categories like ready-to-eat food items and beauty and wellness products.

The software allows retailers to input unlimited factors as demand variables and influencers to optimize order plans with utmost precision. Order Right comes with predictive alerts and also optimizes inventory for events like new product launches and inventory phase-outs. With built-in promotional intelligence, retailers can optimize inventory for both demand shifts and demand lifts.

Order Right is built for the industry nuances for all retail segments, such as food and grocery, convenience stores, and health, beauty & wellness retail, and has helped businesses achieve:

- 60% reduction in out-of-stock

- 20% reduction in inventory investments

- 10% – 30% reduction in inventory wastage

- Near-perfect shelf availability at all times.

Upgrade from static, siloed inventory demand planning software to a more agile, AI-led inventory demand planning today. Please get in touch with our experts for a self-guided software demo that offers a detailed functional overview of Order Right, and kickstart your inventory demand planning transformation today!

in Sweden from 7 - 8 October 2025. Pre-book a meeting to connect with our

product experts.

in Sweden from 7 - 8 October 2025. Pre-book a meeting to connect with our

product experts.