The Retailer’s Guide to Replenishment Optimization: Strategies for Efficient Stock Management

Table of contents

- Demand Forecasting and Replenishment – Understanding the Key Terms

- Why Demand Forecasting Matters

- Traditional Replenishment Planning

- Why Traditional Replenishment Planning Fails to Deliver Hyperlocal Precision

- Taming the Chaos: AI-Led Automated Replenishment With Hyperlocal Precision

- Benefits of AI-led Replenishment Optimization

- Five Core Components of Replenishment Optimization

- Use Cases of Replenishment Optimization in Retail

- How AI-led Replenishment Optimization Improves Stock Allocation

- Order Right: AI-Led Demand Forecasting and Auto-Replenishment With Hyperlocal Precision

Studies reveal that businesses lose over $1.7 trillion every year because of poor restocking decisions. In North America alone, that loss touches $349 billion. And these aren’t just routine slip-ups. They reveal something deeper, broken links in how inventory is forecasted, placed, and managed on the ground.

Retailers today are caught between shrinking margins and rising consumer expectations. Demand changes fast. Buying doesn’t happen only at stores, so the old ways of planning just can’t keep up anymore.

What is needed is not just automation, but a smarter, more adaptive approach. One that aligns inventory planning decisions with store-level realities and improves availability without overstocking.

This guide explores that shift. It unpacks the evolution from conventional forecasting and rule-based planning to intelligent, data-driven replenishment optimization. You will find essential concepts, practical use cases, and benefits of leveraging AI in demand forecasting and inventory optimization processes.

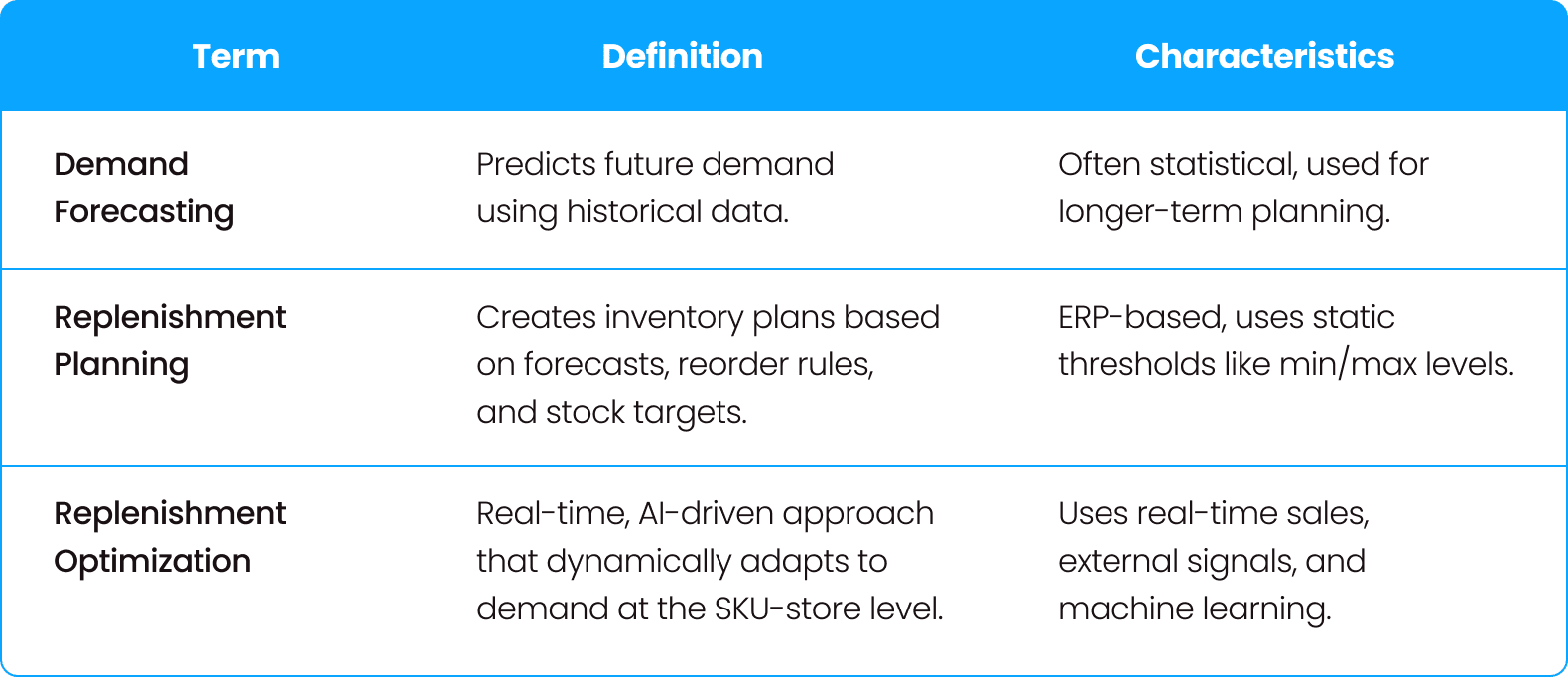

Demand Forecasting and Replenishment – Understanding the Key Terms

Why Demand Forecasting Matters

Inventory optimization is a highly complex process that requires careful and exhaustive analysis of demand influencers and location-specific sales influencers at play, and that too for each SKU and store. This means that, until the retailers decode what to put where and in what amount, avoiding stockouts or overstocks is not possible.

This is where demand forecasting and planning enters the picture.

Identifying and forecasting accurate demand at the SKU-store level arms retailers with a microscope – they can zoom in to visualize the demand and inventory interplay for each store, as well as zoom out to understand the regional behavior.

Hence, inventory optimization stands on the groundwork laid with demand forecasting accuracy. The higher the accuracy, the more optimal the inventory is.

This is why replenishment optimization software with a built-in forecasting engine performs way better than standalone software or tools stitched together. They give a robust framework to plan the entire inventory optimization process from start to finish. The AI-led demand forecasting and inventory planning software work at the store and SKU level, which helps retailers stay ahead instead of reacting late.

Traditional Replenishment Planning

Traditional inventory planning is largely deterministic. It depends on static parameters that believe in a ‘one-size fits all’ approach, such as reorder points, safety stock levels, and historical averages. Typically integrated within ERP systems, this planning approach assumes that future demand mirrors the past. It rarely accounts for the volatility introduced by sudden weather changes, promotions, or shifts in consumer behavior. As a result, offline retailers frequently face challenges like capital lock-ins, missed sales opportunities, and increased storage costs, despite using planning software.

Same replenishment logic. Two different store behaviors. One costly mismatch.

Why Traditional Replenishment Planning Fails to Deliver Hyperlocal Precision

Standard, one-size-fits-all replenishment planning falls flat when it comes to achieving precise inventory at a granular level. While regional planners often apply informed judgment, considering demographics, climate, and historical data, the rules they create (like safety stock levels or reorder triggers) are still static and standardized. These thresholds don’t adjust in real time and are rarely tailored to the unique behavior of each store.

The result is a persistent mismatch between stock and store-level demand planning, which hinders inventory optimization.

A high-footfall urban store may consistently run out of key items during evening peaks, while a low-traffic outlet receives more than it can sell. It leads to expiry, markdowns, or write-offs. This isn’t a result of poor planning effort, but of rigid logic that simply can’t respond to local, fast-moving variables.

AI-led replenishment planning approach addresses this gap by using dynamic, SKU-store-level intelligence. It continuously adapts based on real-time demand signals, enabling localized decisions that evolve as conditions change.

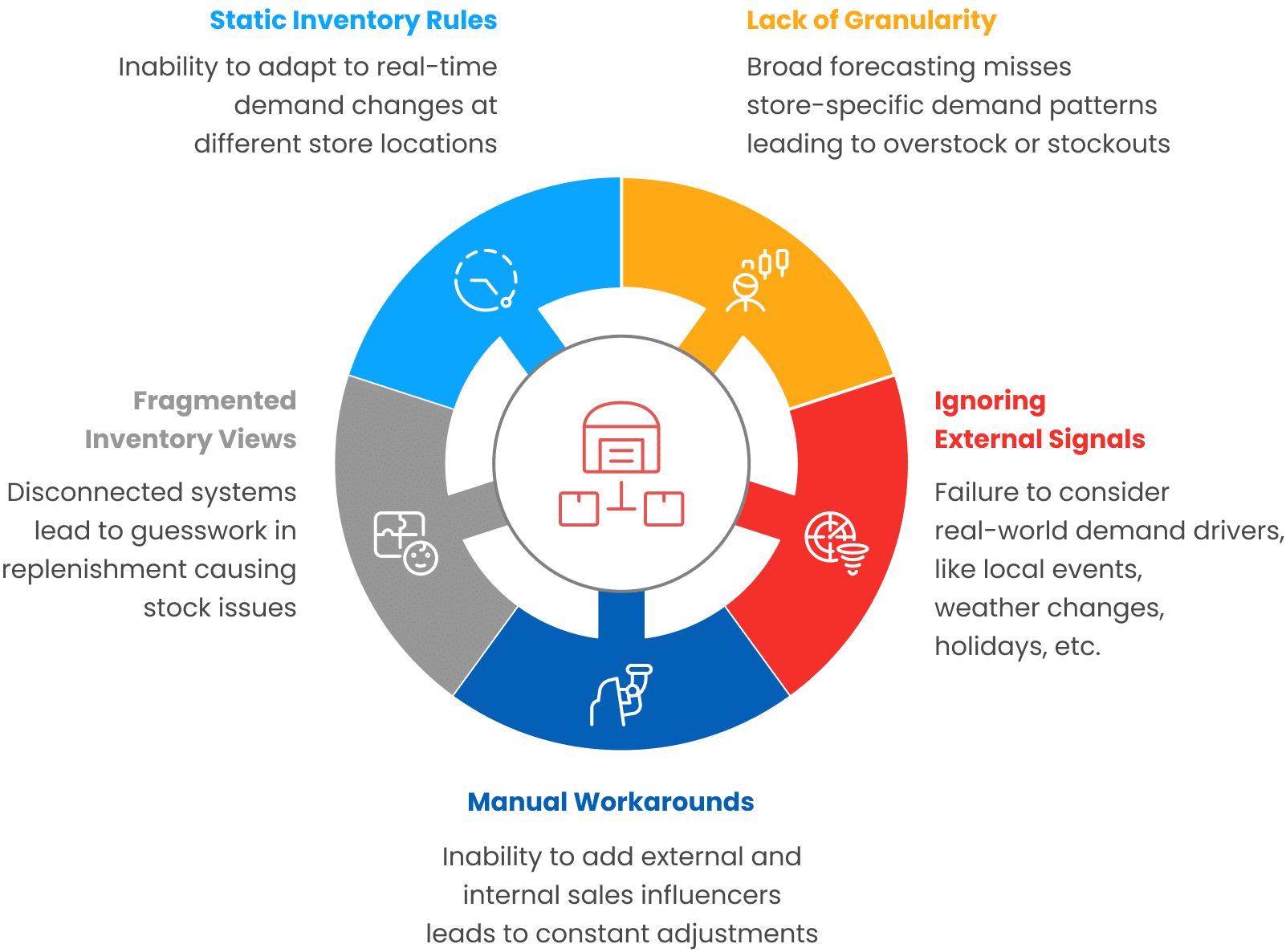

Challenges in Traditional Replenishment Planning

-

1. Static Inventory Rules Can’t Keep Up

Most planning systems still rely on fixed reorder points or min/max thresholds. These rules don’t adjust in real time, even when there’s a sudden spike in demand or a local event. The result? You’re either stocking out at peak hours or sitting on inventory that won’t move.

-

2. Forecasting Without Granularity

Forecasting often happens at the regional or category level. That’s useful for broad trends, but demand patterns change from store to store, for every region, which is why high-level planning falters. A high-footfall store in a metro reacts very differently from a low-traffic outlet in a tier-2 town. Without SKU-store level precision for planning inventory, you’re allocating stock blindly.

-

3. No External Signals = No Real-Time Smarts

Most replenishment planning methods don’t factor in local holidays, climate shifts, or even live promotions. These are real-world demand drivers. Without them, even the best forecasts fall flat.

-

4. Manual Workarounds Are the Norm

Because the system logic is too rigid, retailers are constantly firefighting, tweaking orders, overriding logic, and fixing mismatches. That’s not optimization. That’s survival mode.

-

5. Fragmented Inventory Views

On-hand, in-transit, and reserved inventory often sit in different systems. Without one connected view, replenishment becomes a guessing game. You risk ordering stock that’s already on the way or missing replenishment opportunities altogether. Apart from bloating the inventory investments, this can also increase the warehousing costs.

Taming the Chaos: AI-Led Automated Replenishment With Hyperlocal Precision

AI-led demand planning and inventory planning, by contrast, is a dynamic, intelligent process. It’s not just about reordering when levels drop. It’s about forecasting need at the SKU-store level using real-time data feeds.

AI-Led Auto-Replenishment vs Traditional Replenishment

AI-driven replenishment planning solution continually learns, predicts, and adjusts based on changing demand signals. They reduce human dependence, automate complexity, and enable true just-in-time inventory optimization without compromising service levels. As a result, retailers meet customer demand through reduced inventory while planning for all kinds of demand surges and declines.

Benefits of AI-led Replenishment Optimization

High Shelf Availability at All Locations

Real-time demand planning allow retailers to maintain optimal stock levels of their best-selling SKUs. Rather than relying on outdated forecasts, planning inventory with dynamic replenishment strategies ensures that products are available at the right time and place.

No More Constant Firefighting

Rather than reacting to out-of-stock alerts or overstocks, the planning system fine-tunes replenishment at the individual store and SKU level. This means the supply closely matches local demand patterns for each store.

Less Spoilage, Fewer Markdowns

AI-driven inventory planning systems bring a new level of control to high-risk categories like ready-to-eat and fresh produce. By factoring in variables such as shelf life, expiration dates, and localized buying patterns, they enable timely, accurate ordering.

This leads to better product rotation, fewer markdowns, and a more efficient planning of short-shelf-life inventory, ensuring fresh stock reaches the shelf when it’s needed most.

Granular Insights at SKU Inventory

AI-driven replenishment systems don’t just forecast broadly — they optimize inventory at the product-location level. This means each SKU at each store receives tailored stock order recommendations based on its unique demand profile, footfall patterns, and constraints like shelf space, delivery cycles, or regional preferences.

Retailers can further customize these recommendations by setting model selection criteria or applying their existing business logic for exhaustive planning. Such smart configurability empowers them to maintain just the right stock at every location, which means no understocking, no overstocking, and no blanket rules.

Improved Profitability

AI-powered replenishment software directly impacts profitability by planning and optimizing stock across every node of the supply chain. Overstocks are minimized, reducing holding costs and markdowns. Stockouts are prevented, protecting sales and customer experience.

During high-impact periods like promotions, the system dynamically adjusts recommendations and planning to avoid cannibalization between SKUs and ensures the right inventory mix across locations.

Additionally, for perishables and short-shelf-life categories, lower spoilage contributes to tighter margin control. Together, these capabilities lead to stronger vendor alignment, better shelf performance, and measurable improvements in profit per square foot.

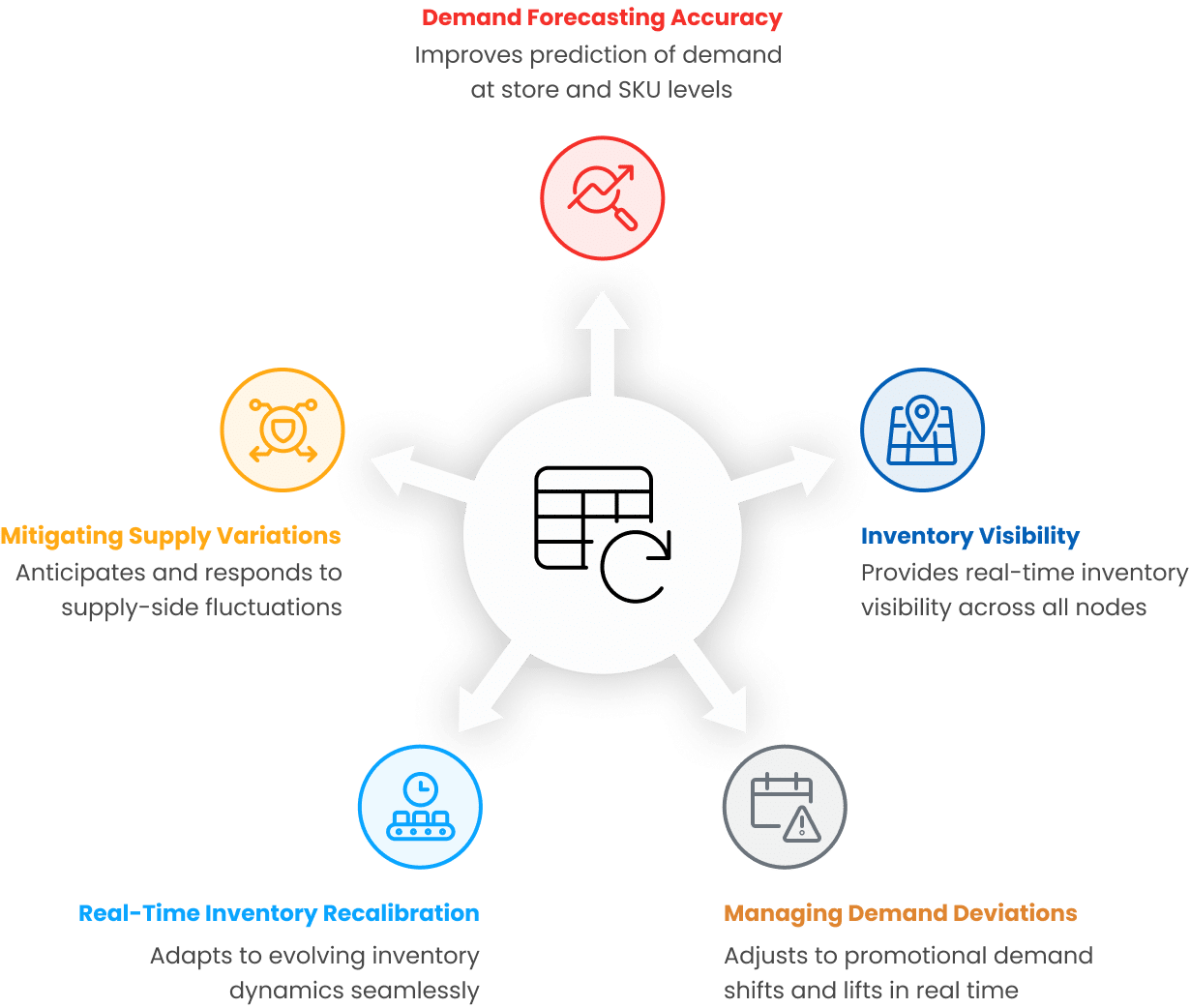

Five Core Components of Replenishment Optimization

Core Components of Replenishment Optimization

Inventory planning and optimization is not a one-dimensional improvement but a holistic framework comprising multiple interdependent systems. Each component addresses a specific barrier in the traditional stock and inventory planning cycle and, together, they ensure that replenishment becomes more responsive, resilient, and cost-efficient.

-

1. Demand Forecasting Accuracy (Store-SKU Level)

Legacy demand forecasting models overlook the granularity needed to forecast demand at individual store and SKU levels. Intelligent replenishment solutions effectively bridge this gap by learning from sparse or noisy data. They pick up on diverse constraints and numerous factors like seasonality, neighborhood buying patterns, holidays, and weather changes.

-

2. Inventory Visibility Across Nodes

Inventory optimization requires more than knowing what’s on hand. It demands a unified view across every node in the supply chain, like store shelves, stockrooms, warehouses, and goods in transit. Real-time visibility must also include perishability, packaging constraints, and stock condition to make data-driven inventory decisions.

With complete transparency across the network, retailers can act smarter: rerouting products before expiry, substituting items when needed, and holding back supply when demand drops unexpectedly. This kind of multi-echelon inventory planning based on intelligence turns visibility into action.

-

3. Managing Demand Deviations During Promotions

Unlike traditional min-max rules that treat all days equally, an AI-driven auto-replenishment framework dynamically adjusts to promotional demand shifts in real time. For example, the system can automatically recognize a Friday before a holiday weekend and recommend higher inventory for promoted items, without oversupplying adjacent or cannibalized SKUs.

This allows retailers to not only capture increased sales but also protect margins by maintaining the right mix across the entire category. Critical planning constraints, such as vendor pack sizes and delivery windows, are also factored in to ensure the plan is practical and executable.

-

4. Real-Time Demand-Based Inventory Optimization

Intelligent auto-replenishment software adapt seamlessly to evolving inventory dynamics. Whether it’s the sudden introduction of a new SKU or the planned phase-out of an existing one, these systems respond without disruption.

Built on hierarchical forecasting frameworks, they recalibrate demand predictions even when data is limited or noisy. This ensures replenishment recommendations and inventory planning remain accurate and automated, maintaining consistent product availability despite ongoing shelf-level changes.

-

5. Mitigating Supply-Side Variations

Advanced demand planning and automated replenishment platforms are built to anticipate and respond to supply-side fluctuations. These intelligent planning frameworks allow retailers to configure a wide range of parameters, such as days of stock, on-hand warehouse inventory, and vendor-specific lead times for optimal stock allocation.

With the ability to factor in dynamic supply constraints, the system recalibrates replenishment recommendations in real time. This flexibility enables supply chain teams to respond proactively to disruptions, ensuring accurate ordering and sustained product availability across the network.

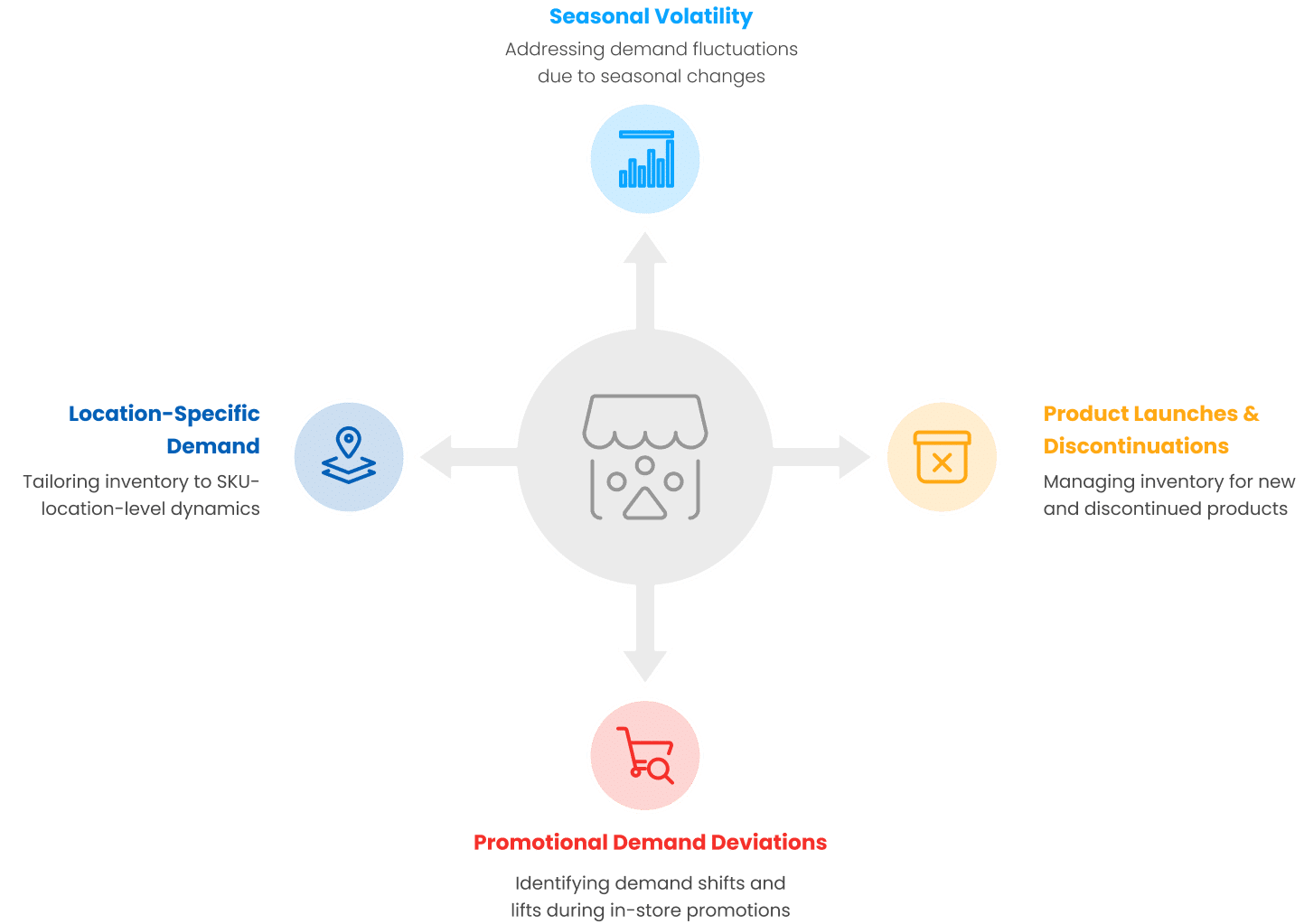

Use Cases of Replenishment Optimization in Retail

-

1. Understanding Seasonal Volatility

Seasonal changes have a direct impact on both demand and product shelf life. A sudden rise in temperature or humidity can reduce the shelf life of products. Seasonal shifts also lead to supply delays, affecting stock availability.

Seasonal demand shifts compound the problem of decoding the right stock allocation for each store location. While the unit costs are still smaller for quick consumables, the high-value SKUs such as cosmetics, wellness products, gourmet grocery items, etc., can lead to huge losses if inventory piles up.

Retailers need store-level forecasting and planning that accounts for weather, shelf life, and what people buy in each location. With the right inputs, they can adjust inventory in time and avoid losses from spoilage or missed sales.

-

2. Managing Quick Product Launches and Discontinuations

New product launches and phase-outs often disrupt inventory balance. Most planning systems are slow to react, which leads to either stockouts or leftover stock that eventually gets written off.

Further, traditional demand planning and replenishment software come with static demand modeling that has a standard, one-size-fits-all approach. They are unable to generate accurate demand forecasts due to limited data from quick product launches and discontinuations. This affects the replenishment planning as well, leading to either stockouts or overstocks.

With AI-led demand forecasting and replenishment solutions, retailers can respond faster and accurately. They learn from similar categories and come with a hierarchical forecasting framework that can consider a diverse set of demand and sales influencers during the replenishment planning.

Thus, retailers can ensure that high-demand products are always stocked in the right amount, at the right locations, while avoiding stockouts. They empower the retailers with firm control over their inventory, and they can order slow-moving items without running out of stock or piling up the inventory.

-

3. Capturing and Modeling Promotional Demand Deviations

Promotions tend to drive demand in unexpected ways. While the demand lifts for promoted items are still accounted for in some inventory replenishment tools, the demand shifts and lifts happening in different categories go unnoticed. Thus, without proper demand planning, retailers end up with piles of stock of low-demand items and run out of stock for high-demand items.

This depletes the retailers’ revenue in multiple ways – loss of sales due to stockouts, capital lock-ins due to overstocks, and increased inventory holding costs. AI-led demand planning and replenishment solutions, like Order Right, identify and manage cannibalization inherently, which means retailers can run profitable promotions every time, irrespective of their number, category, region, or nature.

Ability to sell more during promotions, without ending up with extra stock boosts profitability and helps reduce inventory investments as well.

-

4. Adapting to Location-Specific Demand

Customer demand is not the same everywhere. It changes based on location, local events, and who shops in that area. Standard replenishment planning solution doesn’t capture these local patterns.

This means retailers are planning demand and allocating inventory with a singular vision at a broad level. They are unable to dive into the local demand dynamics and end up with stockouts or overstocked inventory.

On the other hand, AI-led inventory planning and replenishment frameworks, like Order Right, come with thousands of algorithms and allow users to configure the demand influencers and even add their own parameters to create highly accurate location-specific forecasts for each SKU.

Such granular optimization eliminates the need for manual cranking of inventory and cuts down stock issues at scale. All in all, retailers can put the right SKUs at the right location, improve shelf availability, while reducing inventory and spoilage.

How AI-led Replenishment Optimization Improves Stock Allocation

-

1. Accurate Demand Forecasting With Hyperlocal Precision

AI-driven auto-replenishment software starts from the ground level. They capture the demand at the SKU-store level, thereby making it possible to factor in multiple sales and demand influencers, like seasonal shifts, weather, events, holidays, etc.

They can model demand for millions of SKU-store combinations while enabling retailers to set custom criteria for forecast modeling and best fit criteria selection. Such granular customization in the inventory optimization and replenishment planning processes improves the quality of forecasts and exceeds the accuracy of planning done by traditional systems.

-

2. Break Free from Rule-Based Guesswork

Traditional demand planning tools come with static rule-based replenishment, such as days of stock, minimum stock, etc. However, the actual demand doesn’t operate that way. It changes throughout the day, let alone the weeks or months.

Further, the demand at a particular store for a particular SKU is also unique and can be highly nuanced from other SKUs, stores, or locations. This is because of the complex interplay of various factors, such as promotions, SKU size, and more. Such factors cannot be captured by the rule-based replenishment systems for inventory optimization.

On the other hand, AI-led replenishment solutions not only capture these influencers but also capture the demand deviations introduced by in-store promotions.

-

3. Store-Specific Inventory Allocation

Traditionally, retailers allocate inventory with a standard one-size-fits-all approach because they are unable to go deeper into the store-level demand dynamics. This leads to stock imbalances, leading to overstock at one location with the product running out of stock at another. Both situations lead to revenue loss, which could have been avoided.

AI-led inventory replenishment solutions help retailers allocate inventory with SKU-store level precision for all locations. This offers multiple benefits – loss of sales due to stockouts is reduced, loss of revenue caused by overstocking also goes down, and retailers are able to sell with less inventory, without compromising shelf availability.

-

4. Managing Demand Deviations Due to In-Store Promotions

In-store promotions are tricky to manage as they not only lead to demand shifts but also to demand lifts across multiple categories and SKUs. As the demand for the promoted item goes up (demand lift), that item can go out of stock unless sufficient stock is pre-ordered in anticipation of the promotion.

At the same time, unless the ordering of the non-promoted item is sufficiently curbed in advance, that item can be overstocked, leading to unnecessary inventory holding costs and even expirations.

AI-led replenishment optimization solutions inherently overcome these challenges by identifying and managing these demand deviations. They consider the promotional data right from the start, and it becomes part of an ongoing inventory optimization process. Thus, retailers can balance the demand deviations dynamically to avoid both overstock and stockouts.

-

5. Agility, Adaptability, and Allocation, At Scale

Agile inventory calibration, adapting to demand volatility, and planning optimal inventory allocation – these three are the core pillars of operational excellence in the retail supply chain. Demand planning and replenishment optimization software empowers retailers with all three in an effortless manner.

Retailers can automate both demand forecasting and replenishment processes at scale, achieving optimal inventory at all locations. With configurable parameter selection, such as display constraints, minimum order quantities, etc., they can eliminate manual intervention in the store inventory optimization, while reducing inventory costs, stock issues, wastage, and inventory itself.

Order Right: AI-Led Demand Forecasting and Auto-Replenishment With Hyperlocal Precision

Algonomy’s Order Right is an AI-powered demand forecasting and auto-replenishment solution that allows retailers to unlock hyperlocal inventory precision at scale across diverse industry segments, like convenience, food and grocery, and health, beauty & wellness retail.

Order Right comes with a built-in demand forecasting engine that comes with thousands of optimization algorithms tuned to the retail nuances. The retailers can choose and add custom parameters for model selection, optimization constraints, and external as well as internal sales influencers.

They can set the forecast frequency as per their requirements and get highly accurate forecasts for each store location. These forecasts are then used to automatically generate replenishment recommendations that are responsive to supply-side deviations, fill rates, minimum order quantity, and more.

Order Right comes with a powerful suite of functionalities that allow retailers to centralize their demand planning and replenishment processes and manage them effortlessly from a single, intuitive dashboard.

Its hyperlocal forecasting frameworks allow retailers to forecast accurate demand for all types of products, slow movers, new launches, discontinued products, etc. They can overcome the replenishment hurdles like long-tail SKUs and short shelf life items that form a significant portion of the inventory in different segments and can have a detrimental impact on the revenue.

Further, the retailers can overcome cannibalization by analyzing the demand patterns and getting predictive alerts for multiple other events, thereby unlocking the ability to contain incidents before they evolve into business risks.

Order Right has helped retailers across all segments unlock:

- 60% Reduction in Out-of-Stocks

- 22% Improvement in Inventory Turnover

- Improved shelf availability

- Reduction in wastage

- Reduce spoilage by cutting overstocks

Catch Order Right in action. Talk to our experts to learn how Order Right can drive growth for your business.

in Sweden from 7 - 8 October 2025. Pre-book a meeting to connect with our

product experts.

in Sweden from 7 - 8 October 2025. Pre-book a meeting to connect with our

product experts.