Convenience stores face unique inventory planning challenges, ranging from distinct buying preferences in specific segments to fluctuating customer demands based on factors such as the time of day, local events, seasonality, and microtrends. The introduction of mobile apps and ultra-fresh categories, such as food service, has its unique supply chain challenges. With little room to make adjustments on the go, planning accuracy becomes vital.

Integrating AI-based capabilities in demand planning and replenishment can help C-store retailers unlock higher shelf availability, improve inventory ROI, and reduce shrinkage and wastage.

01 Multivariate Demand Planning

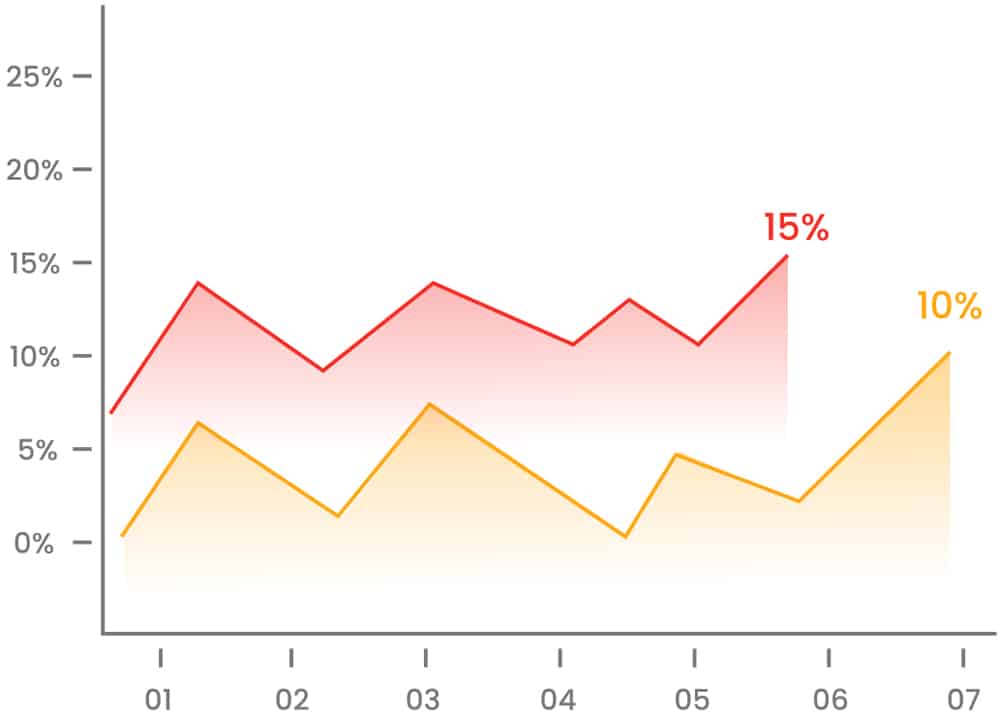

Accounting for external factors enables retailers to improve forecast accuracy by 10 to 15%, which drives cost savings across inventory, transportation, and obsolescence,

Intelligent replenishment solutions offer multivariate demand forecasting while factoring in seasonal changes, local events, weather patterns, lead times, storage space, and more at an ultra-granular level for each channel, store, and category.

02 Overcoming Data Challenges

As many as 50% of brands identify unifying online and in-store operations and data as one of the biggest challenges.

A1-driven demand forecasting handles challenges such as sparse, noisy data and outliers relatively easily. It automatically enriches data and uses hierarchical techniques to ensure the demand is captured at an aggregate level before translating it to the SKU level.

03 Managing Promotional Complexities

Hunch—based promotional strategies cannibalize sales Of other products or cause lifts and shifts in demand, leading to revenue losses instead of boosting sales.

Al/ML-based promotions planning overcomes the complexities of promotional mechanics well ahead of time. It generates highly accurate order plans while simulating demand shifts and lifts at channel, store, and category levels, thereby keeping the profits intact.

04 Streamlining Supplier Collaboration

Improved collaboration in the supplier network directly influences as much as 20% of total revenue.

With quick product discontinuations and new product introductions, efficient supplier communication is critical in C-store retail. Automation-powered supplier collaboration platforms unify data and streamline communication across the entire supplier network ensuring effective collaboration.

05 Dynamic Product Mix

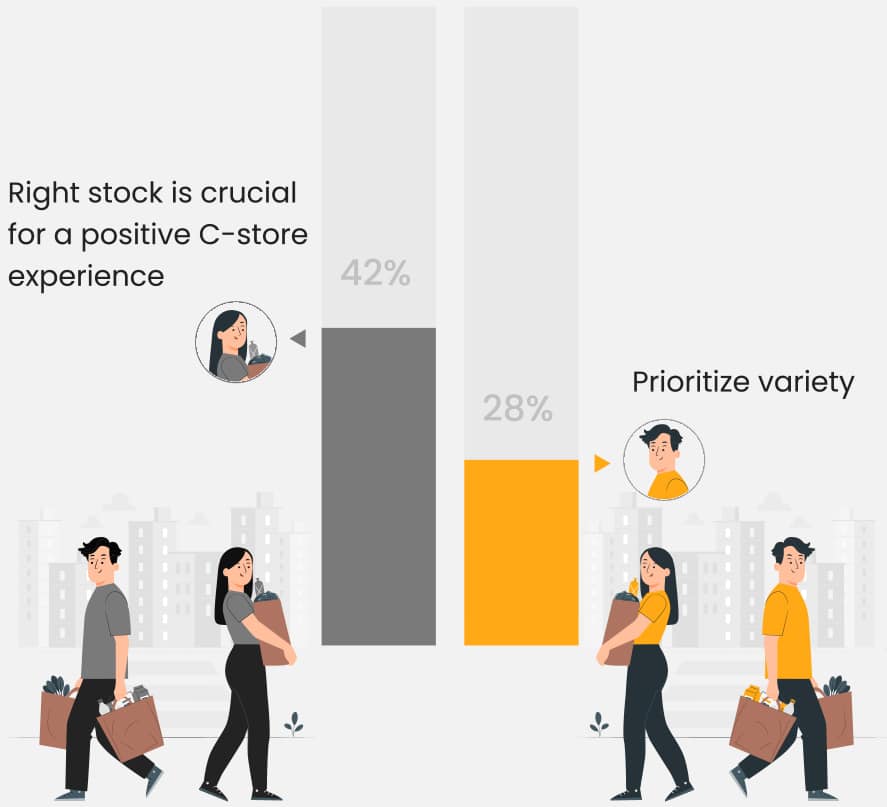

42% of customers say having the right stock is crucial for a positive C-store experience, and 28% prioritize variety.

ML and A1-driven replenishment comprehend demand and supply fluctuations at the minutest product and location levels and enable retailers to operate with less inventory without risking stockouts.

Take your replenishment planning to the next level with Order Right.

in Sweden from 7 - 8 October 2025. Pre-book a meeting to connect with our

product experts.

in Sweden from 7 - 8 October 2025. Pre-book a meeting to connect with our

product experts.