Applicable Segment(s):

Applicable Segment(s):

Grocery Retail, Convenience Stores, Health Beauty & Wellness

Impacted Function(s):

Impacted Function(s):

Supply Chain, Merchandising

Solution:

Solution:

Order Right: Replenishment Optimization

Managing Demand Deviations During Promotions With AI-Powered Replenishment

Promotions are just like the castling in chess. Move the king a bit too much toward the corner, and the opponent might potentially attack the squares the king moves through, and your strategy goes in vain.

Likewise, order more units of a product in steadily high demand and you can end up with huge overstocks due to demand shifts. Or, order less than the regular amount, and you can end up with empty shelves due to demand lifts during promotions.

Often termed as product cannibalization, or inter-SKU effect, or halo effect in retail, this change in product demand owing to promotional dynamics stems from poor or static demand planning.

Cannibalization wipes out as much as 17% of the extra sales volume generated by promotions.

Understanding Cannibalization: Causes and Consequences

In-store cannibalization happens when the demand shifts from one product to another similar product despite the overall demand for the two products remaining more or less unchanged.

Unavailability and promotions are two common drivers of in-store cannibalization. During promotions, the demand for the non-promoted item tends to shift to the promoted item. The magnitude of this shift depends on the nature of the promotion, brand loyalty, and brand equity of the products concerned.

Similarly, when one product is unavailable or has low shelf visibility due to insufficient stock, the demand can shift to the available product.

Now, in the case of promotions, as the demand for the promoted item goes up (demand lift), that item can go out of stock unless sufficient stock is pre-ordered in anticipation of the promotion.

At the same time, unless the ordering of the non-promoted item is sufficiently curbed in advance, that item can be overstocked, leading to unnecessary inventory holding costs and even expirations.

Replacing Guesswork with Accurate Demand Planning

Be it promotional or induced by out-of-stock events; cannibalization stems from inaccurate or static demand planning or forecasting.

Using predictive analytics in demand planning to analyze hundreds to thousands of internal and external demand-influencing variables and machine learning approaches for complex relationship modeling can reduce forecasting errors by 30-50%.

Accurate forecasts form the basis of replenishment planning, and AI-powered forecasting can reduce supply chain errors by 30 to 50%, shrinking lost sales by 65% and warehousing costs by 10 to 40%.

Managing Cannibalization at Granular Level - How Does Order Right Help?

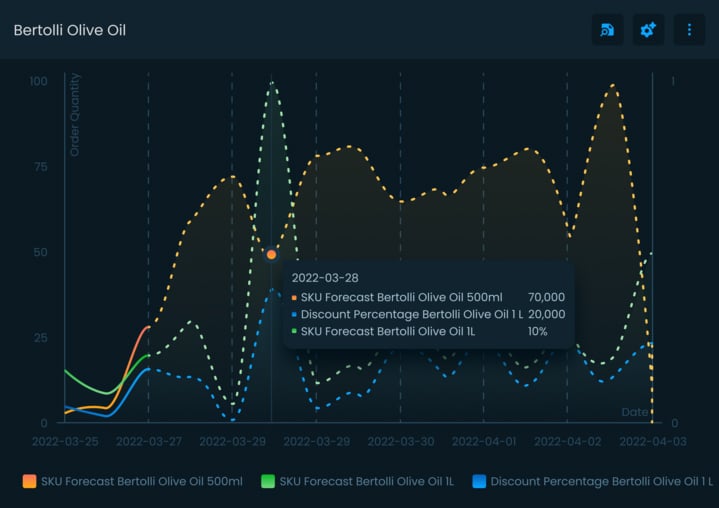

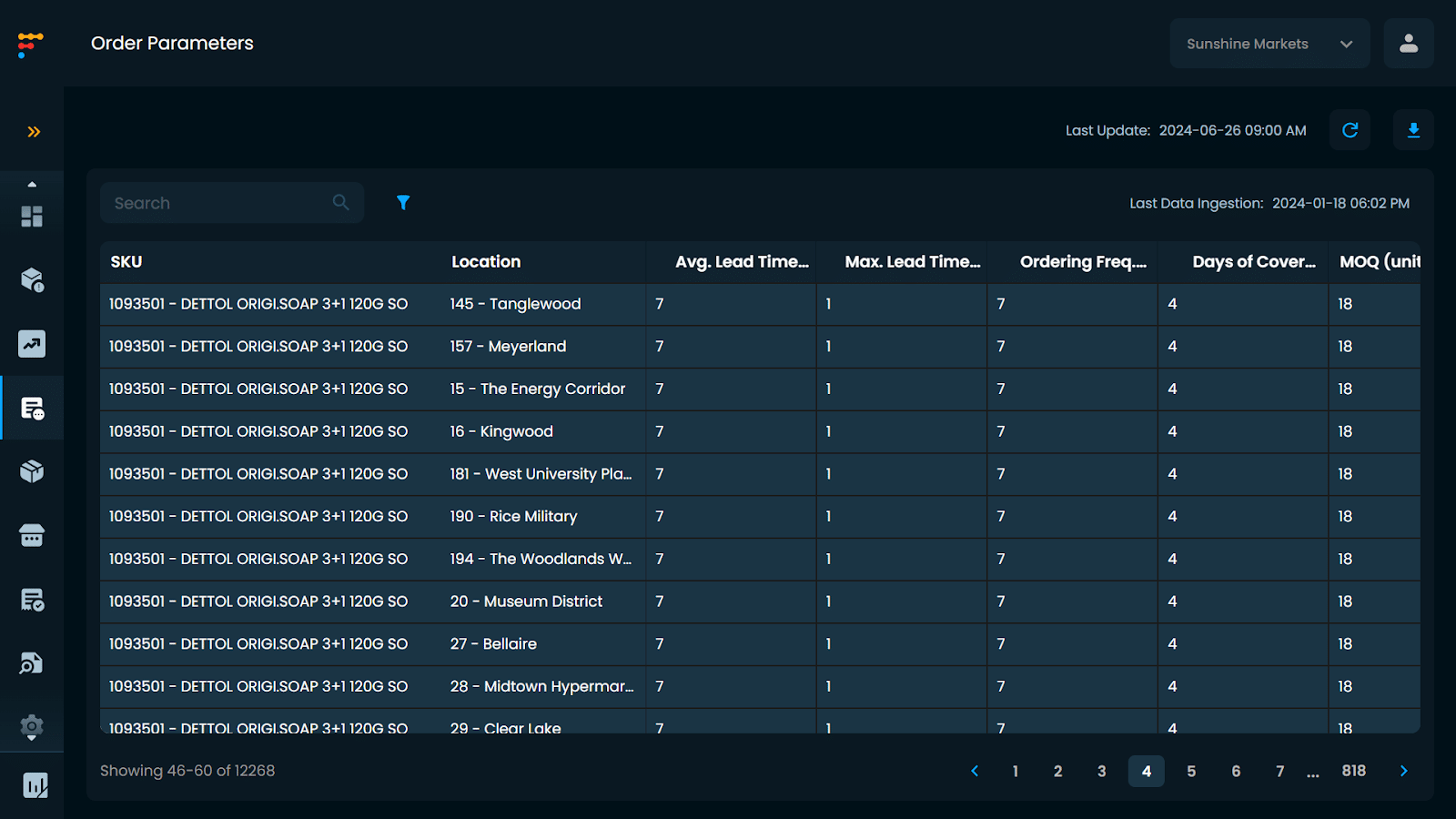

Algonomy’s Order Right generates replenishment recommendations based on forward-looking demand. This means it first processes and understands the promotion calendar and then generates/updates the forecasts accordingly.

Since the forecasts are considered in the replenishment order recommendation algorithm as an input parameter, they account for demand lift and demand shift induced by cannibalization.

The following is a closer look at how this happens.

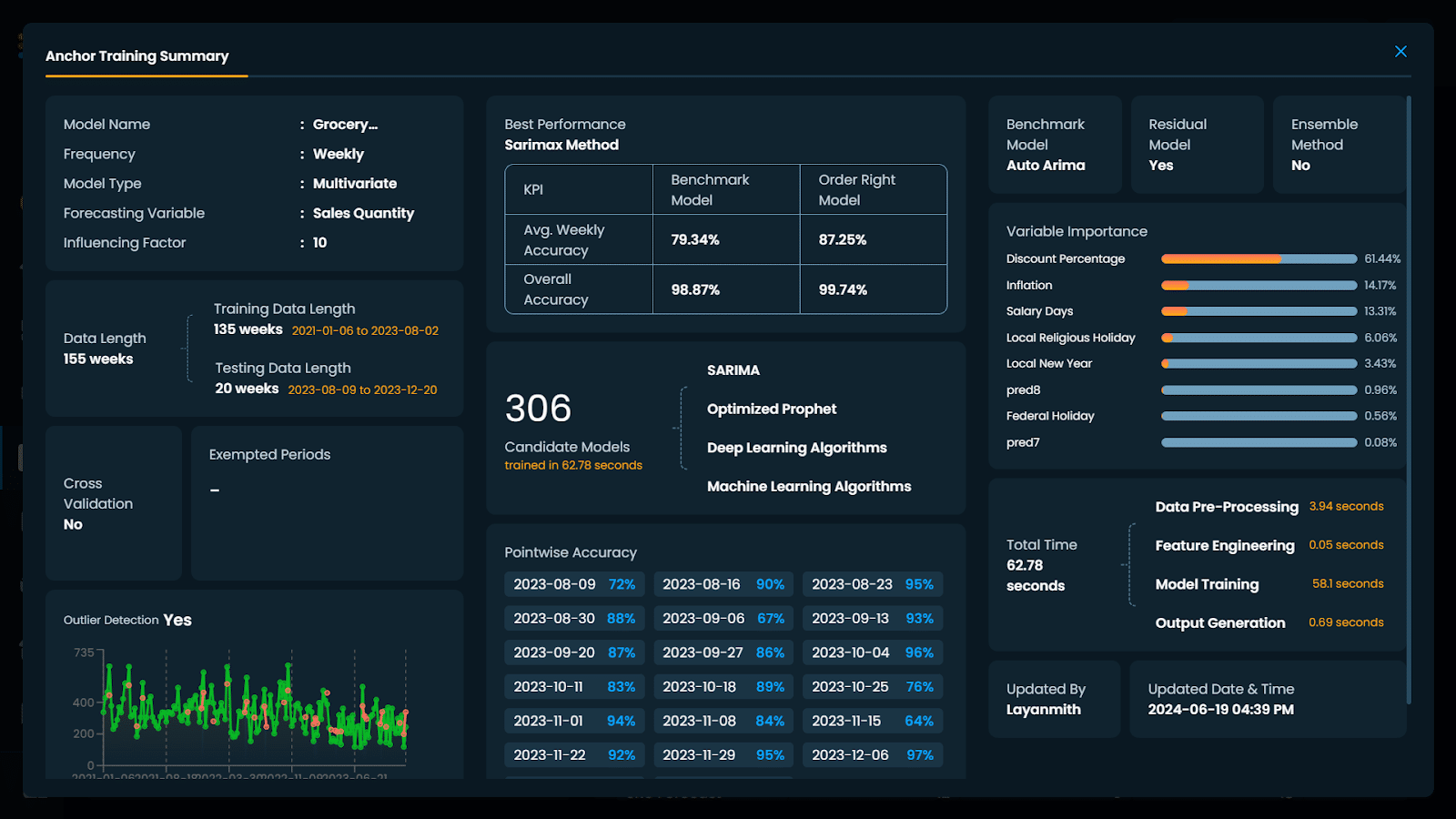

Once the data standardization is done and all the sales-influencing parameters are put in place, Order Right leverages Machine Learning ensemble algorithms and multivariate forecasting to generate hyperaccurate forecast models for each product location combination.

As mentioned above, this is also the stage where the past promotion data is considered on an ongoing basis, i.e., every time forecasting is done.

Now, Order Right automatically decides the priority of various sales influencers, including promotions, for forecast modeling and predicting the sales of a product.

As Order Right generates the future demand based on these models, it continuously includes the promotions calendar and pricing information in forecasting. It predicts sales uplift and shifts for each product based on the promotions calendar.

The forecasts serve as input for the proprietary AI-based replenishment engine to generate highly optimized and intelligent replenishment schedules or order plans based on supply chain constraints.

Order plans are automatically adjusted for promotional effects, thereby reducing excess inventory and avoiding stockouts simultaneously.

Order Right leverages both AI and ML to generate highly intelligent replenishment plans that significantly reduce overstocks, out-of-stock instances, and inventory costs while improving shelf availability. The ability to optimize multi-echelon inventory directly at product location levels reduces wastage and keeps gross margins safe from erosion caused by supply chain disruptions, demand fluctuations, in-store promotions, and more.

Algonomy’s Order Right is helping retailers across the globe to unlock awesome benefits like:

- 75% Reduction in Out-of-Stock Instances

- 10% Reduction in Inventory Costs

- 10% Reduction in Out-of-Stock Instances

- 99% Improvement in Shelf Availability