Are your food and grocery stores oscillating between overstocks and stockouts, irrespective of historical data analysis and automation-driven stocking?

Massive scale of operations, high vulnerability to expiration and markdowns, and promo effects – here are five strategic blind spots that skew your inventory projections and erode revenues globally.

01 Massive Scale of Operations

Forecasting & Replenishment Not Tuned for Massive Scale

Food and grocery retail spans millions of SKUs and categories. Traditional planning tools don’t offer modeling sophistication and hyperlocal planning at such a scale.

Retailers forecast for all categories uniformly, while demand changes at the SKU level.

AI Fix: Offers demand forecasting & replenishment planning with SKU-Location level precision.

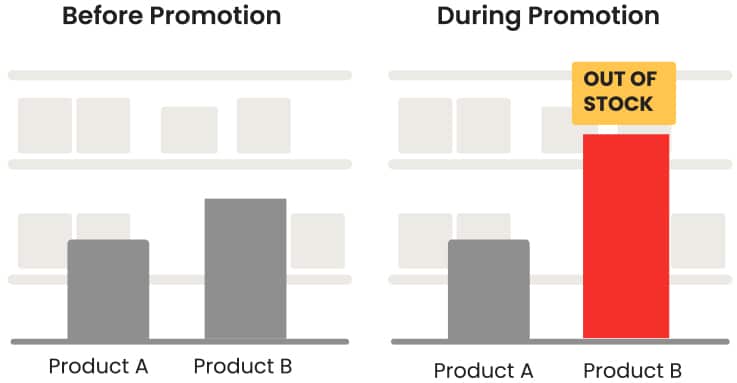

02 Promo Blind Spots

Planning for “Lifts” but Missing “Shifts”

Promoted products pull demand from regular items. Hence, non-promoted items are overstocked, while promoted items go out of stock.

Retailers end up losing promo revenue despite planning.

AI Fix: Models both demand lifts & demand shifts → balanced shelves, higher ROI.

03 Vendor & Supply Variations

One-size-fits-all tools ≠ Real World

Traditional demand forecasting tools ignore vendor calendars, blackout days, fill rates, and more.

Retailers juggle multiple systems, only to end up with stock imbalances and revenue loss.

AI Fix: All supply/vendor-side factors are auto-integrated into replenishment plans.

04 Siloed Planning

Looking Only at Store Stock

Reactive planning doesn’t optimize inventory scattered across the WH, DCs, and dark stores.

Plans are limited to store view, leading to stock imbalances and wastage.

AI Fix: AI Fix: Holistic stock visibility across all nodes → higher turnover, less waste.

05 Vulnerability to Stock Wastage & Markdowns

Overstocks = High Wastage + Markdowns OOS = Loss of Sales

Traditional tools lack modeling sophistication for stock optimization. Retailers have to keep the stocks high at all times to prevent OOS, bearing wastage.

AI Fix: Penalized overstocking and rank-based stock distribution reduce wastage and prevent stockouts.

The Takeaway

AI-led Replenishment = Strategic Edge

Accurate forecasts

Agile & adaptive order plans

End-to-End Inventory Optimization

Resilience + ROI in volatile markets

Stock

smarter.

Waste

less.

Sell

more.

Take your replenishment planning to the next level with Order Right.

in Sweden from 7 - 8 October 2025. Pre-book a meeting to connect with our

product experts.

in Sweden from 7 - 8 October 2025. Pre-book a meeting to connect with our

product experts.